+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

Purlins, also known as trusses, are actually roof beams that are perpendicular to the roof truss and used to support the roofing material, in order to reduce the span of the cabin panels and secure the roof panels. Purlins are transverse bending members, our more common types of solid belly purlins and light steel truss type of these two.

1.Solid belly purlin

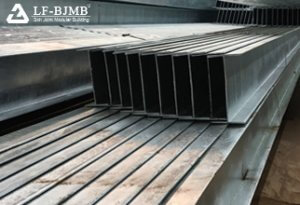

The section of solid belly purlin should be perpendicular to the roof slope, and can be divided into channel steel purlins, Angle steel purlins, H-type steel purlins, rolled groove purlins, composite channel steel purlins.

Channel steel purlins are divided into ordinary channel steel purlins and light channel steel purlins. The thickness of the steel material of the ordinary channel steel purlin body is thicker, so its stiffness can not be fully utilized, so compared with other types, the amount of steel is larger.

Although light channel steel purlins are improved compared with ordinary channel steel purlins, they are still not ideal. Angle steel purlins are convenient to draw materials, but the stiffness is poor, the amount of steel is large, and it is only suitable for the span, purlin distance and the load is small.

High-frequency welding light H-beam purlin: This type of H-beam steel web is thin, stiffness is good, good bending resistance, flange plate than other steel purlins are more flat, easier to install connection.

Rolled troughed cold-formed thin-wall steel purlin: This type of rolled troughed purlin has a larger cross-section and higher interchangeability, so it is not only less steel, but also more convenient to install, so it is also widely used.

Rolled Z cold formed thin wall steel purlin: This kind of purlin, its stiffness is strong, small deflection. It uses less steel and is easy to manufacture. Not only that, Z-shaped steel purlins can be stacked, occupy less space, easier to store.

Composite channel purlins are welded by two Angle steel, and the amount of steel is less than that of ordinary channel steel, but the welding workload is large, and it is suitable for the span ≤4m.

2. light steel truss purlin

The upper chords of trussed purlins should be perpendicular to the upper chords of the roof truss, while the belly and lower chords should be perpendicular to the ground. It is composed of Angle steel (upper and lower strings) and plate welding, and its main feature is that it uses less steel and can make reasonable use of small Angle steel and thin steel plate.

All the rods of light steel truss type are cold-formed thin-wall steel, which is suitable for the roof of big purlin distance, with less steel, clear force and large stiffness inside and outside the plane. The main part of the purlin upper chord and end vertical pressure rod are made of cold-formed thin-wall steel, and the rest of the rod is made of round steel material, which is mostly used for the roof of 1.5m purlin distance.

If there is no purlin, the span of the steel plate will cause excessive deflection. It can be seen that purlins play a very important role in construction. However, regarding the type of purlin, the construction should also be selected according to the actual situation.