+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The waste incineration power plant has two MSW incineration lines with a daily processing capacity of 300T and two 6MW power generation lines.

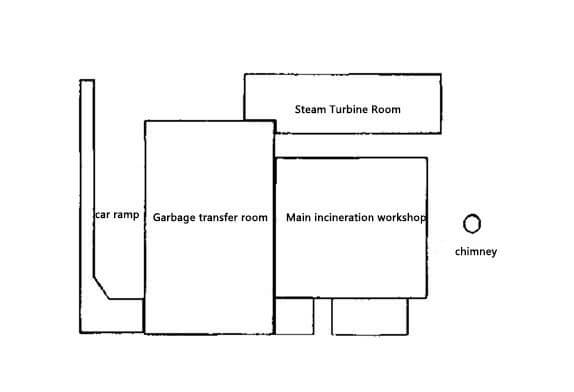

FIG. 1 General plan of waste incineration power plant

The trash incineration power plant consists of three structural units: a waste transfer room, the main incineration workshop, and a steam turbine room (see Figure 1).

1) The waste transfer room adopts a cast-in-place reinforced concrete frame structure. The floor of the internal waste pit is mass concrete, and the surrounding is connected with the strip foundation of the frame frame frame frame column. The bottom and side walls of the garbage pit are designed with double-layer reinforced concrete to improve its impermeability and corrosion resistance. The roof of the garbage transfer room adopts a space frame structure. There are two heavy-duty electric bridge cranes (9.5T) inside.

2) The steam turbine room adopts a cast-in-place reinforced concrete frame and frame structure. A steam turbine foundation is designed according to the power foundation. The steam turbine roof adopts a light roof trapezoidal steel roof frame. It is equipped with two intermediate working electric bridge cranes (16T / 3T).

3) The main incineration workshop is a space steel structure. In order to meet the process requirements, there are no columns or beams on the side bordering the garbage transfer room, which becomes an open space structure workshop. The roof adopts a curved double-layer space frame with a skylight.

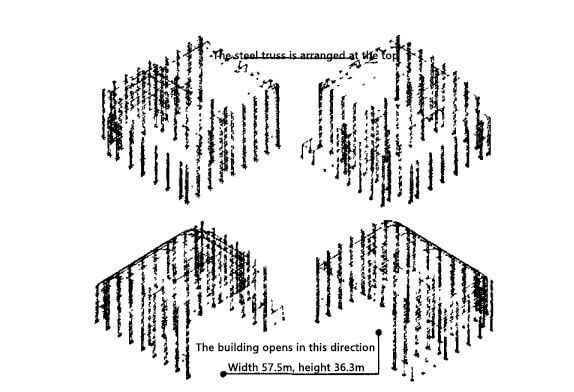

FIG. 2 Design effect diagram of main incineration workshop

FIG. 3 Structural space model

The basic seismic intensity of the garbage incineration power plant project site is 6 degrees; The site category is III, and the foundation is pile foundation; The basic wind pressure is 0.45 kN/m2.

The main incineration workshop is a highlight of the architectural design of the project, as can be seen from the renderings, the roof of the circular arc, enhances the dynamic and spatial sense of the whole building, but also increase the difficulty of structural design. The interior of the main incineration workshop contains various main equipment of the project: incinerator and waste heat boiler between axis 9 and 18, reaction tower and dust collector between axis 18 and 27, and fly ash curing device between axis A and D. These main equipment are tall structures, arranged in the main incineration plant are very compact. Therefore, the main incineration workshop is a single-story building, in addition to the building around the column, only a row of columns can be installed in the middle of the workshop. Also, because the incinerator is directly connected to the waste transfer room and there are many connected pipes, it is not possible to install columns on this side of the main incineration plant.

In the area where the incinerator and waste heat boiler are located, the height of the workshop is 36.3m, and the roof is supported by three sides. If the column can be set up on axis 9, the main force direction of the structure should be the letter axis direction because of the different vertical and horizontal spans. But because 9 axes can not set the column, so, the main force direction of the structure tends to be the digital axis direction.

In the area where the reaction tower and dust collector are located, the height of the workshop is 36.3m ~ 18.1m, and the roof is supported by four sides and is arc.

Due to the arc roof’s large horizontal force, the structure’s main force direction in this area is the direction of the letter axis.

The height of the workshop is 28m in the area where the fly ash curing device is located. The main structure form can be understood as a single-layer frame. Due to the three areas of the main structure form is not completely consistent, the structure of the main stress direction is not entirely – cause, and together with each other, work together, become a whole, therefore, the form of the calculation and analysis, cannot or bent to the framework of conventional design, only as a space structure of integral calculation and analysis, to achieve accurate results.

The failure of steel structure is yield failure, belonging to ductility failure, and steel structure is lightweight, high strength, and easy to install, so it is easy to achieve a more complex building posture, easy to achieve a larger span of the structural system. The waste transfer room and steam turbine room of this project are reinforced concrete structures, but the main incineration workshop is a space frame structure.