+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

Light steel structure is the abbreviation of light steel structure. This is a new type of structural system that has only been developed in recent years, and has been rapidly promoted and popularized in just a few years. Because of its simple, quick and efficient manufacture and installation, many manufacturers have launched production. The space frame structure appeared earlier in our country. The early and mid-1990s was its most glorious period . Today, this structure can still be seen in gas stations, toll stations and large stadiums. The characteristics of these two structures are analyzed below.

1 Structural analysis

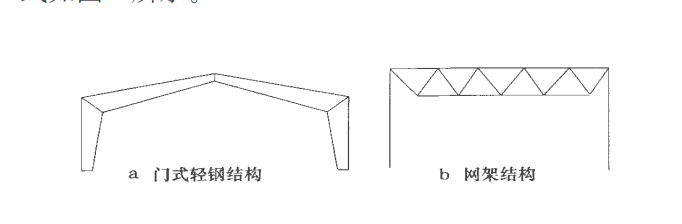

The light steel structure and space frame structure belong to the steel structure category, and the basic form is shown in Figure 1.

1.1 Light steel structure

Light steel structure is a plane force system, and the most commonly used one is portal light steel structure. It generally consists of three parts, the main structure is composed of columns, beams, trusses, canopy , etc.; The column is generally a single unit member, and the beam can be divided into several units according to the transportation conditions . The unit members themselves are welded , and the units can be connected by high-strength bolts through the end plates.

Light steel structures generally adopt columns of equal section or columns of variable section, and beams of variable section. The maximum span of a single span can reach 48m , and the economical span is less than 30m , which can provide effective usable space . The economical distance between each steel frame beam is 6~9m, and the roof slope can range from 1.3 to 1.30. There are single span,

Double-span, multi-span and other forms , corbels can be added to the H-shaped columns , crane beams can be placed , and the maximum height of the cornice can reach 15m.

The steel used for the light steel structure shall comply with the relevant regulations. For load-bearing cold-formed thin-walled steel, light hot rail steel and steel plate, etc., the Q235 specified in the current national standard “GB700-88 Carbon Structural Steel” and “GB/T1591-1994 Low Alloy High Strength Structural Steel” should be adopted. Q355 steel. When there is a reliable basis, other grades of steel can also be used. Q235 takes σ b =235N/mm 2 , and Q355 takes σ b =3 5 5N/mm 2 . For the exterior walls of light-weight houses, in addition to light-weight walls using profiled steel plates as enclosures, masonry walls or exterior walls with masonry at the bottom and light-weight materials at the top can also be used. The roof of a light-weight steel structure house has a small self-weight, and its bearing capacity is generally not controlled by the combination of seismic actions, so seismic calculations are usually not performed.

1.2 Space frame structure

The space frame structure is a structural form in which the space is stressed as a whole . The stress is transmitted between the rods through bolt balls, and the rods themselves are not affected by bending moments and shear forces. It has a variety of structural forms, classified according to the space frame composition, including cross truss systems, quadrangular pyramid systems, triangular pyramid systems, curved surface space frame systems and other special-shaped systems. The selection of the space frame frame should be determined through comprehensive analysis in combination with the design elements of the project’s plane shape, span size, support, load size, and roof structure. The layout of the space frame rods must ensure that there is no structural geometry change.

The main accessories of a complete space frame system include bolt balls or welded balls, high-strength bolts, steel pipes, hinge supports, etc. Ordinary section steel and thin-wall section steel can be used for space frame rods, and high-frequency electric welded steel pipes or seamless steel pipes can be used for pipe fittings . When conditions permit , thin-wall section should be used. The steel of the rod should meet the requirements of the national standard “GBJ17-88 Steel Structure Design Code”. The cross-section of space frame members should be determined through calculation and checking according to the bearing capacity and stability.

For the external load of the space frame structure , the load in the area under the jurisdiction of the node is concentrated on the node according to the principle of static force equivalence. In structural analysis , the influence of node stiffness can be ignored , assuming that the nodes are hinged , and the rods only bear axial force. When there is a local load acting on the member, the influence of bending should be considered. Due to the specificity of the force , the space frame structure can provide a large span space and realize a column-free design, which can meet the use requirements regardless of vertical, horizontal or vertical. Due to the uniform internal force transmission, the unit lifting point can provide a large suspension load to meet various needs.