+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

一、Project Overview

University of Science and Technology Beijing Gymnasium consists of 8 000 seats competition hall and a standard pool natatorium with a total construction area of 23,993m. It is one of the main competition venues of the Beijing 2008 Olympic Games.

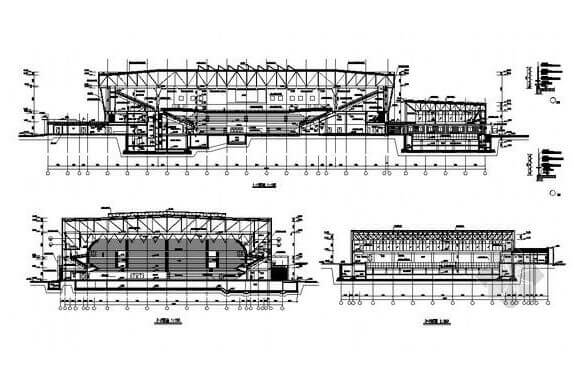

The roof span of the competition hall is 76.8m from east to west and 105m from south to north, while the roof span of the natatorium is 60m from east to west and 30m from south to north. Both roof structures adopt steel space frames.

FIG. 1 Structural elevation of the gymnasium

FIG. 1 Structural elevation of the gymnasium

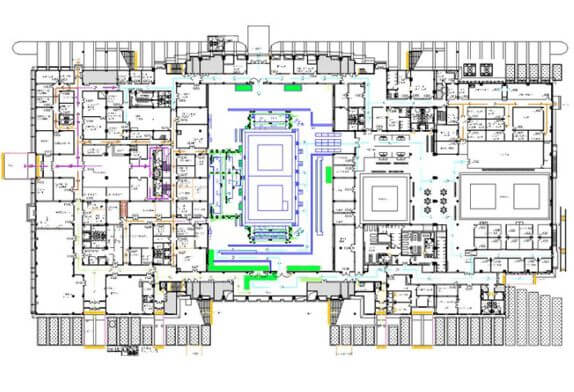

FIG. 2 Structure plan of the gymnasium

The space frame span of the competition hall is large, and there are hanging equipment layers on both sides of the east-west direction. The gables at both ends of the north and south are hanging glass curtain walls. The total load of the roof is large (the average standard load value is 3.66KN /m). According to its characteristics, the design adopts the form of an improved bi-directional straight space frame, that is, without increasing the number of belly bars and nodes, two oblique chord systems are added in the upper and lower chord planes. Not only the internal force of a single rod is effectively reduced, but also the reaction force between different supports is adjusted. At the same time, because of the increase of these oblique rods, improve the overall roof in the oblique mechanical performance, but also reduce the space frame overall stress on a single rod, effectively improving the safety performance of the structure.

The main structure of the competition hall uses 516t of steel. The steel quantity index is 6kg/m. The calculated deflection is 285mm(1/70 of the short span), and the pre-arch is 150mm in construction. Natatorium main structure of steel 66t. The steel quantity index is 7kg/m. The calculated deflection is 104mm(1/88 of the short span), and the pre-arch is 60mm in construction. The space frame structure has strong design flexibility. If the rod is arranged reasonably and carefully according to the specific characteristics of all aspects of the project, it can not only ensure the safety and applicability of the structure but also achieve good comprehensive benefits in aesthetics, economy, and other aspects.

二、 Analysis of the characteristics of the horizontal structural system of the gymnasium

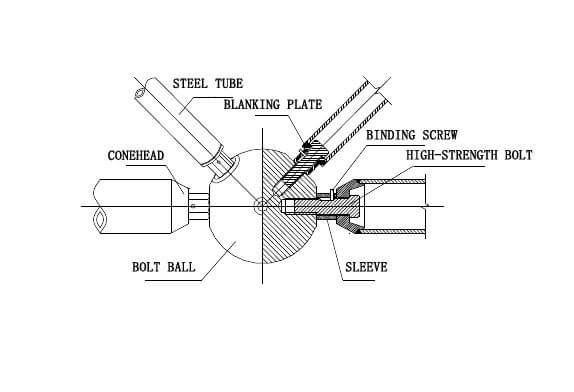

There are many steel structure members on the roof of the gymnasium, which affects the lighting effect of the skylight, but makes the whole structure more firm. The steel structure of the roof of the University of Science and Technology gymnasium is a bolt-ball steel space frame structure. The structure of the steel space frame is relatively easy to understand. The whole roof looks like a “net” composed of many rods. The joints of the rods are spherical and have holes to fit the bolts on the rods. To make full use of space, a lot of equipment in the stadium is directly hung on the steel space frame, which increases the load, the rod is heavy, and it puts forward higher requirements on the node force.

FIG. 3 Diagram of space frame structure

The solution is to add diagonal bars based on the original quadrilateral space frame so that the original quadrilateral space frame into a triangle space frame. This improvement looks simple, but it adds a lot of rods to the steel roof truss at once. The number of rods is more, the force of each rod is correspondingly reduced a lot, the commonly used force characteristics, with the shortest load transfer route, uniform force, and so on.

三、Analysis and evaluation of the advantages and disadvantages of the engineering structural system:

Advantages:

1. Bolt-ball node space frame is a new load-bearing roof structure developed rapidly in China in recent years. It has the characteristics of large spatial stiffness, belonging to the spatial structure system, neat space frame, uniform rod, good integrity, lightweight, large spatial stiffness, and strong seismic performance.

2, all bolt connection between the rod, no welding deformation, convenient installation, easy to transport and packaging, all components of the space truss made in the factory, reliable quality, well can reduce the amount of work on the construction site, saving steel and other characteristics, very suitable for standardization and commercial production.

3, it can save steel than steel roof frames by 20%~30%, the reinforced concrete structure can reduce the weight by 40%-60%, and the construction period can be shortened 2~3 times.

Disadvantages:

1. Quality control is most likely to occur in the welding of the bolt-ball node space frame.

2, design to consider the Angle of the rod, the Angle is not good bolt ball is very large.

3, the bolt ball is solid, the single weight is large, and the field installation is difficult.

4. High precision of each accessory is required.