+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1. Project Overview

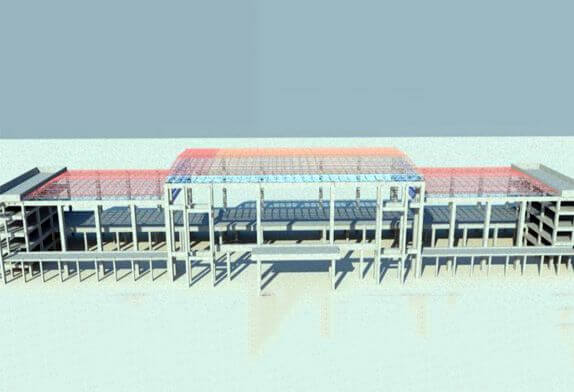

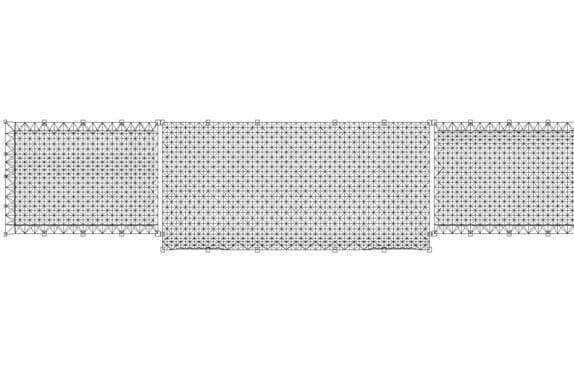

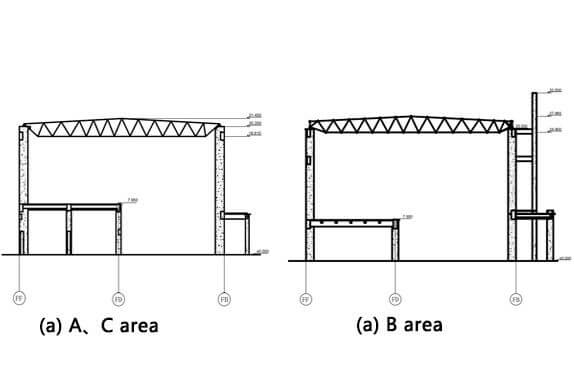

The roof of the main station landlord’s station of Nanchang Station is a space truss and steel space frame supported by the chord under the square pyramid. The axial view is shown in Figure 1-1. The space of the station house is a typical space system of unequal heights, and the unequal heights section is shown in Figure 1-3. The main body is divided into three zones A, B, and C. Zone B (the middle part of Figure 1-1) and Zone A and C (the left and right parts of Figure 1-1) are unequal-height structures with A height difference of 6m. The plane projection is square with A width of 40.0m from north to south and A total length of 204.0m from east to west. The dimensions of the roof space frame rod are ф 60×3.5, ф 76×4, ф 89×4, ф 114×4, ф 140×4.5, ф 159×6, ф 159×10. The dimensions of the main space frame in the three areas are 48m×35m (zone A and C) and 84m×40m (zone B). The layout of the structure is shown in Figure1-2.

Figure 1-1 Axle view of the roof of the steel space frame of the east

Figure 1-2 Space frame structure layout diagram

Figure 1-3 Section view of unequal height structure

2. Slip method space frame construction scheme selection

The project has a long east-west span of 204m, which leads to some difficulties in high altitude scattered piecing and overall lifting, so the sliding method is preferred for construction. Slip refers to the preset on the slippery course of elements of a sectional plane slip to a particular design, combined into a whole, is a kind of advanced construction method of spatial structure for large volume, large longitudinal length, and high large-span space truss structure, sliding method has obvious economic and technical advantages, has been widely used in many engineering, Several common slippage schemes are described below.

2.1 Construction process of space frame structure slip method

The sliding method of space frame structure means that the position of the assembled tire rack is fixed. After the assembling of the space frame structure is completed, the assembled unit slides to the design position and then the assembling of the next unit. The sliding method of space frame structure has the following characteristics:

(1)The number of brackets required for installation is less, which can save the time and cost of bracket installation;

(2)The installation of the main structure is always carried out in a fixed area, which is convenient for construction operation and management and conducive to ensuring construction safety;

(3)The requirements of lifting equipment and traction equipment are not high, a small crane or winch can be used, and even a hand hoist can be used for traction and simple construction. The slippage of the space frame structure can be divided into the block slippage method and the cumulative slippage method. Block slippage method refers to sliding one truss which has been assembled or hoisted to a fixed design position, and then assembling or hoisting the second truss and sliding it to a specified position to connect with the previous one. This operation is repeated until the installation of the last truss is completed. The cumulative sliding method is a common structure first slip the distance of the width of the cross, and then install the second natural, structure and the former one common together, two common structure with sliding distance, and combine the third common structure with the second nature, structure, link up the three common structure for the slip, this cycle operation, until the very last one common joint structure. The block slip method requires the sliding main body to have good stability inside and outside the plane. The required traction force or thrust force is not large, so it can adapt to the long-distance slip, but the installation error is large. In the cumulative slip method, several trusses of space frame frames are assembled into slippage units with good stability and then slippage to the design position, which requires greater traction or thrust and smaller installation error. If the longitudinal span of the structure is large, the combination of the two ways can also be used.