+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1 Project Overview

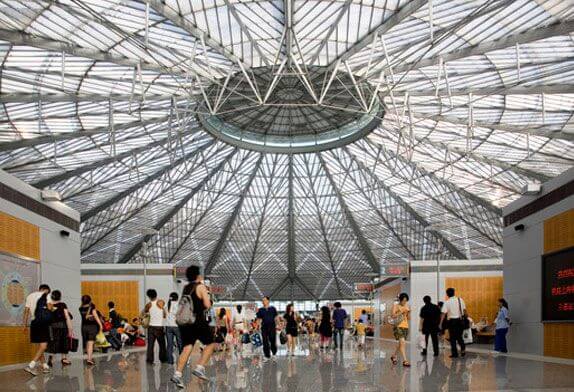

The roof of the airport terminal hall takes into account the architectural needs of skylight lighting and the giant cable curtain wall of the arrival hall and adopts a space frame roof steel structure with a combination of welded ball space frames and cross trusses. It is mainly composed of 31 tree-shaped bifurcated supporting steel columns and roof steel structures, with a projected area of about 55,000 square meters. The north-south length is about 340m, and the east-west span is about 160m. The roof is composed of welded ball space frames, cross trusses, giant arches, and overhangs. It is connected with steel columns through 82 large cast steel nodes. The vertical height of the space frame is 4-6m, and the total steel consumption is about 8000t. . The roof steel structure model is shown in Figure 1. The main joint forms of the roof steel structure are welded ball joints, intersecting joints, cylindrical joints and cast steel joints.

2 Selection of installation method

Large-scale venues in China have experienced rapid development for nearly 20 years, with a large number and many installation methods for roof steel structures, forming relatively mature construction technologies, which can be roughly divided into several categories.

1) For high-altitude in-situ splicing, a scaffolding is set up under the steel structure roof to form a working surface for in-situ installation of steel structure parts. This method is mostly used in various space frame structures. The workload of scaffolding is large and the construction period is long. Other processes cannot be carried out in the area where the scaffolding is erected, and there are many restricted conditions. The advantages are that the measurement and positioning are more accurate and the installation accuracy is higher. At the same time, due to the use of bulk lifting, the lifting capacity of the vertical transport equipment is not required to be high, and the construction cost is low.

2) High-altitude block hoisting roof steel structure for ground block assembly, in-situ installation of supporting tire frames, and direct hoisting in place with large hoisting machinery. This method can be assembled on the ground in advance, the hoisting speed is fast, and the overall construction period is short. However, the hoisting distance is greatly affected by the performance of the hoisting equipment, and it is difficult to achieve long hoisting distance, and the construction cost is high.

3) The steel structure of the overall lifting roof shall be assembled on the ground in situ, using the vertical structure of the building or the installation lattice column as the lifting support frame, and using equipment such as hydraulic cylinders or hoists to lift the roof to the installation position. This method is suitable for roofs with regular roof structure design, single-span structures, circular structures, and less horizontal lifting points, especially suitable for industrial plants, gymnasiums and other building structures. It adopts ground assembly, which has high assembly precision and fast construction speed, but it is difficult to apply to many roofs with complex shapes.

4) For high-altitude sliding, the vertical structure of the building is used to install the sliding track or the sliding tire frame. The roof and the ground are assembled in blocks. After hoisting to the sliding tire frame, the method of block-by-block sliding or cumulative sliding is adopted, which is beneficial to the movement of the hydraulic cylinder. , so that the roof can be installed in place.

The project adopts welded ball space frame and crosses truss at the same time. Part of the area is a landing giant arch truss. The roof is free hyperboloid. It is difficult to meet the construction requirements of the economy, speed and safety by using a single installation method. Therefore, according to the characteristics of the roof steel structure of this project, different support and hoisting methods are adopted for different parts. After research and discussion, high-altitude in-situ splicing is adopted for the welded ball space frame area, making full use of the convenient installation conditions of the existing civil tower crane; Avoid setting up excessive full-room support frames, which will affect the overall construction period.

According to the characteristics of the steel structure roof truss, this project adopts the construction methods of high-altitude splicing and block hoisting, divides reasonable construction sections according to different installation methods and areas, determines the best construction sequence, component hoisting methods, and selects hoisting equipment. Support the tire frame, and completed the construction task on schedule.