+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1 Project Overview

The terminal building of Jinan Yaoqiang International Airport has 2 floors, with a total construction area of 80,000 m², a total length of 486m, a width of 66.7~145m, and a roof height of 14~32m. The plane projection of the roof is in the shape of a bird, with an area of 50406m². It is a hyperbolic space surface formed by the intersection of two symmetrical rings. The radius of the generatrix circle is 200m and the radius of rotation is 900m. The architectural design combines the visual beauty of flying birds and the essence of aircraft technology, creating an open and bright space with a geometric long-span structure. The exposed herringbone steel pillars show the rhythm and lightness of movement.

2 Structure scheme

Terminal floor 1 adopts a reinforced concrete structure, the column mesh size is 15mx15m, and the floor and beams adopt a prestressed reinforced concrete structure.

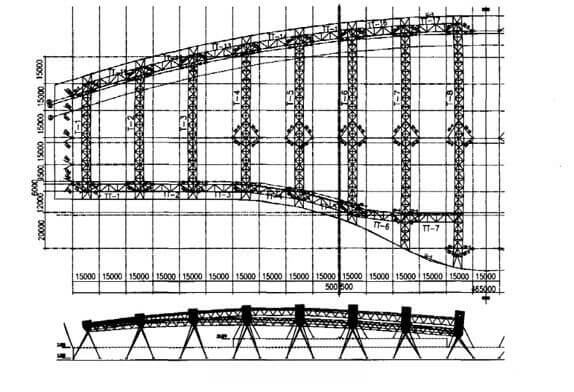

Terminal Building Structural Drawings, Elevation Drawings

The roof of the terminal building is cut by the intersection of two symmetrical rings. Due to the large radius of the rings and the flat geometric shape, combined with the section shape of the building, a space truss structure in which round steel pipes are intersected and welded is used to connect with V-shaped columns at both ends. Form a door-shaped rigid frame system. The trusses (T-1~T-3) of the two wings of the terminal building are single-span, and the maximum span is 76.3m;

Trusses in the middle part (T-4~T-8).

Due to the large span (85.9~122.8m), a V-shaped pillar is set in the middle of the span to become a double-span door-shaped space truss with a maximum span of 62.6+60.2=122.8m (Figure 1). Connecting trusses (TT) are set longitudinally along the glass curtain wall, and the upper chord of the steel trusses is longitudinally set with H-shaped steel arc-shaped roof beams, and the beams are covered with roof supports.

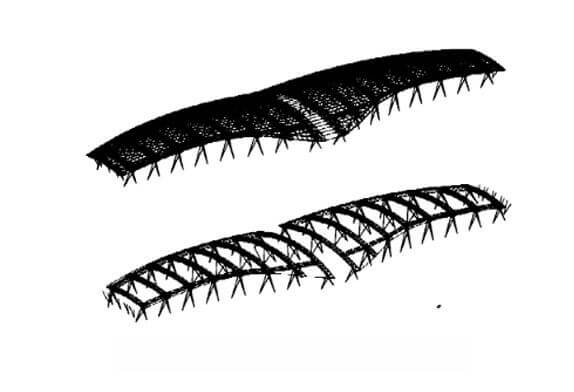

The roof is made of a light heat-insulating metal roof with an undercut and closed. Secondary beams are set according to the node spacing of roof trusses (about 5m), and the span of the secondary beams is about 25m. The section of the space truss is an isosceles triangle composed of three steel pipes as chords, the upper side is 5m long and the triangle height is about 4m. A truss chord is an arc on a ring with the same axis. The gantry columns on both sides are composed of 4 steel pipes, and the 4 supporting columns are all supported on the lower chord node: the middle pillar is also composed of 4 round steel pipes and is supported on the lower chord: the 4 pillars are herringbone in the longitudinal direction and V-shaped in the transverse direction. Each truss itself is a stable structure.

The overall perspective of steel structure and roof truss system

Due to the building space requirements, the distance between the trusses is 30m, and there are only 18 trusses along a total length of 486m. In order to strengthen the in-plane rigidity of the roof system, full cross bracing is set between the roof longitudinal beams, and the roof bracing system strengthens the integrity and stability of the roof. Combined with the suspended ceiling design, a unique roof landscape is created. A space lateral force truss is set along the surrounding glass curtain wall.

The two wings of the airport building are completely symmetrical, and each becomes an independent overall structure. The middle is connected by a section of the glass roof with variable width. The end of the secondary beam and the truss adopts a longitudinally slidable structure to reduce the excessive length of the structure. temperature effect.