+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The space frame structure is a large-span roof structure widely used in architectural engineering. It has the advantages of reasonable force, a large span and a high degree of industrialization, and a flexible layout, and a beautiful shape. It can save materials when meeting the requirements of architectural appearance, so it is widely used in sports buildings and public buildings. At present, there has been a relatively mature network design software, in the process of network design, in order to save steel and reduce the cost, the general use of full stress design method. However, in the case of the full stress design of the space frame, the initial defects of the rod and the use of overload and other factors are more sensitive, in the use of the space frame, due to the use of function change, redecoration, load increase, and other reasons, will make the existing space frame bearing capacity is insufficient. If reasonable technical measures can be taken to reinforce and transform the existing space frame structure to meet the new functions, it can not only save resources and reduce costs to the maximum extent but also conform to the economic policy of “low carbon, energy saving, material saving and environmental protection” strongly advocated by the state.

The roof of the education center stage adopts the vertical quad-cone space frame structure, the plane size of the space frame is 23.4m × 14.3m, the height of the space frame is 1.1m, the node type is welded ball, and the roof board is prefabricated concrete roof board. The use of the net frame before reinforcement is shown in Figure 1. It can be seen that the channel steel arranged on the lower chord of the net frame makes the lower chord bear transverse load, and the force is unreasonable. At the same time, the individual upper chord of the structure has obvious bending deformation.

Due to the improvement of stage use requirements, it is necessary to increase the curtain, scene lights, computer lights and maintenance bridleway and other facilities in the lower string of the space frame to meet the new useful functions. According to the completed drawings of the original space frame structure provided by the owner and the actual situation of the site survey, the space frame structure is recalculated, and the results show that the bearing capacity of the original space frame structure does not meet the requirements, need to be strengthened.

Figure.1 Steel education center space frame

2.1 General technology of reinforcement and transformation of space frame

Before the reinforcement and transformation of the space frame, the as-built drawings of the original space frame should be consulted. The use of the space frame should be investigated on the spot, to check the weld, bolt connection, rod deformation, and bearing displacement, and to detect the deformation, displacement, and deflection of the space frame. Generally, the following methods can be used for the reinforcement and renovation of the space frame:

1) Reduce the load of the original space frame and unload the structure, such as replacing the concrete roof slab with a light steel structure roof;

2) Add a layer of space frame pieces or rods covered with steel welding, ball joints covered with steel sleeves;

3) Increase the bar section, ball joints, and supports that do not meet the requirements in the space frame;

4) Change the support form of the space frame, for example, the original space frame is supported on both sides and can be changed to four-side support;

5) Cross stiffeners are welded outside the ball joints;

6) Add additional support and crossbar to the pressure rod and increase the section of the rod;

7) The ordinary space frame is transformed into a prestressed space frame. This method is to impose a vertical reverse load on the space frame at the lower chord ball node of the space frame through the establishment of a prestressed structural system, so as to adjust the stress level of the rod and the deformation of the space frame.

2.2 Selection of reinforcement scheme for the space frame

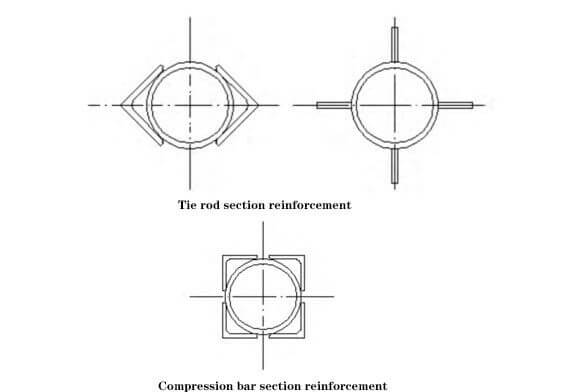

This project mainly considers the following three schemes for the reinforcement of the space frame structure: Scheme one, is to change the reinforced concrete roof plate into a light steel structure roof and unload the space frame structure. In Scheme 2, under the action of new loads, the section reinforcement is carried out on all the over-stressed rods. The section reinforcement method of the rods is shown in Figure 2. Scheme three is to add a layer of net frame in the lower string.

Figure.2 Space frame reinforcement

Scheme one can keep the net height of the interior of the building unchanged, and the construction of a light steel roof can be carried out on the existing space frame, without the erection of scaffolding, so the construction is more convenient. However, this scheme requires the removal of the existing reinforced concrete roof, and the removed concrete roof panels cannot be reused, which is not very economical.

Scheme two can also keep the net height of the building indoors unchanged, if the bar section reinforcement, and the bearing capacity of the upper and lower string ball joints can meet the requirements, the construction does not involve the roof plate, and the construction can only be carried out indoors. The disadvantage is that the temporary support points need to be increased to ensure safety during construction when the section of the space frame rod is strengthened. In addition, when the number of overstress bars of the space frame is a lot, the welding workload of the steel structure will be very large, and the reinforced bar section form is diversified, the appearance is not as beautiful as the round tube.

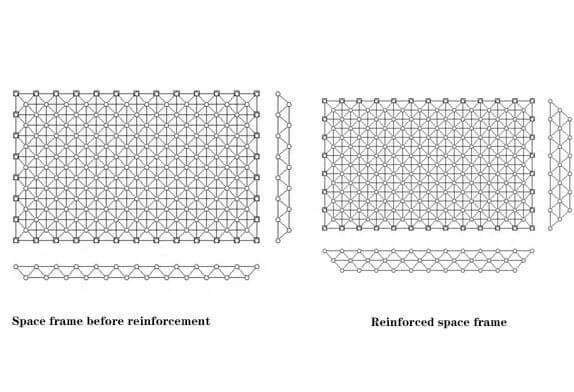

Scheme 3 is to add another layer of net frame on the lower chord of the net frame, as shown in Figure 4 and Figure 5. This solution would reduce the interior net height of the building and would also require the addition of temporary supports, but it would effectively increase the stiffness of the structure, reduce the deflection, and maintain the structural appearance of the original structure. After communication with Party A, in order to ensure that the reinforcement work does not involve the roof to ensure the construction period, and in order to make the reinforced space frame and the original space frame in appearance, the final choice of the third reinforcement scheme, that is, add a layer of space frame in the lower string of the space frame.

Figure.3 Comparison before and after space frame reinforcement

After communication with Party A, in order to ensure that the reinforcement work does not involve the roof to ensure the construction period, and in order to make the reinforced space frame and the original space frame in appearance, the final choice of the third reinforcement scheme, that is, add a layer of space frame in the lower string of the space frame.

3.1 space frame calculation model

In fact, whether it is bolted or welded ball space frame, the space frame node connection is between articulated and rigid, it is difficult to realize the real articulation. In the design of the space frame, usually according to the structure type, node form, and the different parts of the rod, the calculation length of the space frame rod is different, so as to consider the influence of the node stiffness on the bearing capacity of the rod. In general, the influence of joint stiffness can be ignored when analyzing the space frame structure, and the secondary stress is ignored. It is assumed that the joints are hinged and the rods only bear the axial force. However, when there is a local load on the bar, the influence of local bending internal force on the stress of the frame should be considered separately. In the actual force of the space frame, especially for the welded ball space frame , the actual deflection of the space frame is smaller than the calculated value of the hinged scheme due to the existence of the joint stiffness.

3.2 Influence of initial bending of a member on bearing capacity

In the finite element analysis of the space frame, it is usually assumed that all the bars are axial bearing bars. However, in the reinforcement design of the space frame, sometimes the rod of the space frame has appeared a certain bending deformation under the condition of overload. What influence will this initial bending have on the bearing capacity of the space frame? This is the concern of the reinforcement design of the space frame. In fact, in addition to the overload condition, the bending deformation of the space frame rod, rod manufacturing, and installation deviation will cause the initial bending of the rod, resulting in the compression rod into an eccentric pressure rod. In order to evaluate the degree of stability reduction of the rod with initial bending, the experimental and theoretical studies show that the design bearing capacity of the central compression rod is suitable for the initial bending range of l/400 ~ l/140, and is related to the slenderness ratio of the rod. The test results of center loading and eccentric loading for space truss with initial bending of l/880 ~ l/100 show that the ultimate test load of the string is 0% ~ 11.8% higher than the calculated value of the central compression bar when the initial bending is l/800 ~ l/300. It can be concluded that when the initial bending of the truss member is less than l/750, it can be considered that it has no significant influence on the bearing capacity. In addition, the overall stiffness of the space frame will be improved to a greater extent after the reinforcement of the additional layer. With the reduction of the axial force of the upper string compression bar, the elastic compression deformation will be restored to some extent.

3.3 Space frame reinforcement design

Secondary stress and construction process need to be considered because the reinforcement of the space frame is carried out without removing the reinforced concrete roof panel, the structural members already have a certain stress, so the reinforcement calculation must be considered according to the secondary stress. This kind of reinforcement analysis considering secondary forces is different from that without considering secondary forces, because no matter whether adding space frame pieces, or adopting other methods such as bar section reinforcement and prestress reinforcement, it will lead to the redistribution of internal forces of the bars, and this redistribution of internal forces may produce adverse results to the original space frame. The design of space frame reinforcement also needs to consider the construction process, because the supporting conditions of the space frame in the reinforcement construction stage are often inconsistent with the use stage, for example, in this project, the construction of the space frame to increase the temporary support point, so that special attention should be paid to the whole process of the construction of displacement and internal force analysis and calculation, and can be used as the initial internal force and strain of the space frame. In addition, sometimes according to the construction site, the erection of temporary support points for the space frame is difficult, and the space frame can only be welded under the load state. At this time, the welding rods should start from the area with small stress of the space frame, and gradually transition to the area with large intermediate stress, so as to ensure construction safety. In the calculation and analysis, the initial analysis of the original space frame is carried out first. At this time, the load is only taken from the actual dead load of the structure, and the internal force and strain of the space frame are taken as the initial conditions. Secondly, according to the construction of the space frame support conditions and welding order, analysis of the space frame bearing capacity under dead load and construction live load; Then the bearing capacity and overall deflection of the reinforced space frame are checked.

To sum up, the design of space frame reinforcement takes the stress state of the space frame reinforcement as the initial condition and considers the different stress states of the construction stage and the use stage and carries out the whole process analysis. During the analysis, the reinforcement scheme should be adjusted repeatedly to meet the requirements of the economy, safety, and convenient construction.

Before the construction of the space frame reinforcement, the original channel steel and hangers on the space frame should be removed first, and the original space frame should be unloaded. Because the space frame has reinforced concrete roofs and other loads, effective measures must be adopted in the construction process to ensure safety. The construction scheme adopts a full scaffold and provides eight temporary support points in the middle of the span of the space frame, as shown in Figure 4.

Figure.4 Temporary support point of space frame

(1) The space frame rod only bears axial force, is not allowed to hang heavy objects on the rod, and workers are not allowed to walk on the space frame rod.

(2) When welding the space frame, in order to prevent excessive stress, welding is done symmetrically along the length to both sides and gradually to the middle sequence. When welding the lower chord joints of the original space frame, multiple rods should not be welded continuously in the same section, and the next rod should be welded after one rod is welded and cooled.

(3) Add temporary support to the remaining ball joints around the solder joints when welding the lower chord joints of the original space frame. The welding spot should be symmetrical and uniform in the periphery of the space frame, and only one welder is allowed to construct the area where the stress is relatively large in the middle of the space frame.

(4) The electrode used for rod positioning welding should be the same as the electrode used for formal welding. Position welding is intermittent welding, cooling speed is fast, so the welding current should be 15% ~ 20% larger than the formal welding. The arc and arc of the weld should be a smooth transition, so as to avoid cracks or incomplete welding during formal welding.

(5) Before formal welding, it is necessary to check whether there are defects in positioning welding and whether the solder joint is cracked.

(6) When the mesh is assembled and corrected, it is strictly prohibited to hit the belly bar of the mesh with a sledgehammer, which will cause the end of the mesh bar to deform.

(7) the construction site cut-off rod: Generally speaking, the construction of the space frame will meet the situation of the site cut-off rod. Because there is a big difference between the production length of the space frame rod and the site size, it has to be cut off and welded on-site. At this time, the welding parts of the rod should be inspected.