+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1. Overview of Steel Structure Hall Engineering Project

The project of an international hall in Qingdao covers an area of 429 acres. The construction content includes the login hall, exhibition hall A, exhibition hall B, hotel, office building, and energy center. The total construction area is about 631,500 square meters, and the hall engineering design and construction investment are about 6.7 billion yuan.

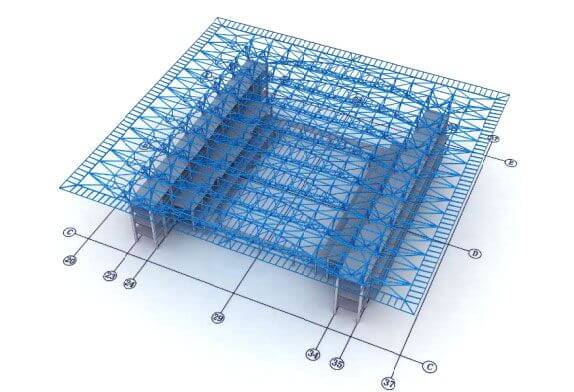

The login hall is located in the middle of exhibition halls A and B of the exhibition center, with a steel structure as the main body, which is the biggest highlight of the exhibition center. The roof of the entrance hall is a large-span steel structure, which is spectacular from a distance. The effect drawing of the steel structure of the entrance hall is shown in Figure 1. The 27.15m four-story frame column supports the roof steel structure, and the steel structure includes roof pipes. The truss and the outer ring box-shaped cantilever beam are 180m long from east to west and 162m long from north to south. The roof steel structure is welded with pin shaft supports and lower steel columns. There are 8 main trusses in the upper part, and the spacing between each truss is 18m. The lower chord and large span of the main truss is a single curved pipe, the upper chord is a straight pipe, and the connecting web members of the upper and lower chords are consecutive rods with a length of 0.6m~12m. the central truss is connected by a round pipe into the arch, the maximum span ratio is 8.2%. Each main truss weighs 410T.

Figure 1 Effect drawing of steel structure hall

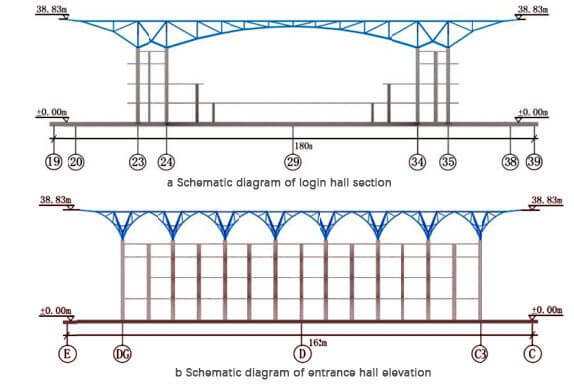

The prefabricated hall is composed of 8 irregular and hyperbolic space tube trusses and connecting rods. The roof elevation is 38.83m, the middle large space span is 94.5m, and the cantilever length on both sides is 26.5m. It is a large-span tube truss structure. , see Figure 2-and Figure 2-b for details. The design arching value of the truss mid-span is 1/500L=189mm, and the deepening pre-arching form is adopted.

Figure 2 a( Schematic diagram of exhibition hall section) and b(Schematic diagram of entrance exhibition hall elevation)

2. Features and difficulties of this prefab steel structure hall project

(1)The volume of the steel hall is large.

(2)The construction period is extremely tight.

(3)The hall construction standard is high. Coordination and management are difficult. The entire project has a large construction area and a large number of monomers, divided into multiple construction areas, and the construction sites are scattered.

(4)The design of the prefabricated hall project is novel and there are many technical difficulties. The steel structure hall project faces many technical challenges, such as excavation of deep foundation pits under complex silt geological conditions near the sea, construction of large-span complex steel structures, construction of large-area self-compacting concrete, and construction of fair-faced concrete with large-volume facing, and crack control of super-long concrete structures.

3 Tire frame installation

High-altitude assembled tire frame

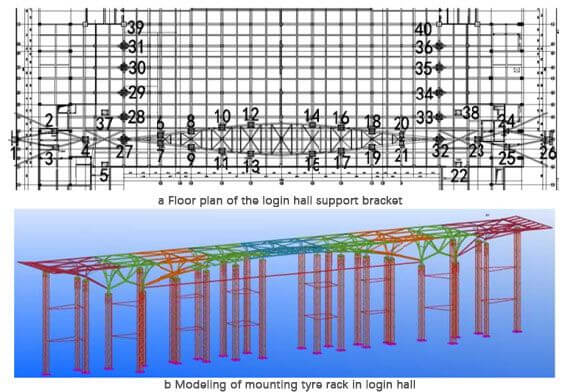

On the south side of the 38.7m of the first main truss of the 2-G axis, on both sides of the 4/2-D axis, a total of 159m from the 2-19 line in the west and the 2-38 line in the east, a total of 28 sets of high-altitude tire frames are installed. The height of the tire frame is 27.15m-37.95m. The flat and vertical surfaces of the tire frame are shown in Figure 3(a、b)

Figure 3 a(floor plan of the login hall support bracket)and b(modeling of mounting tire rack in login hall)

)