+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

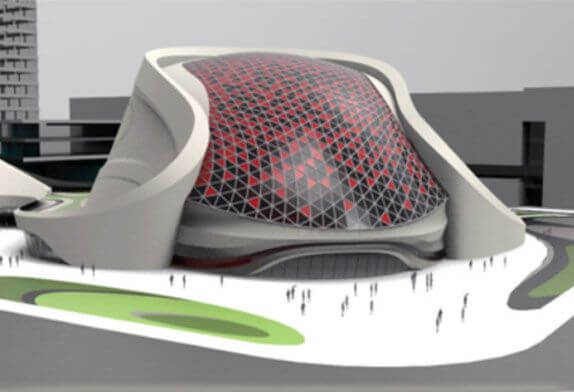

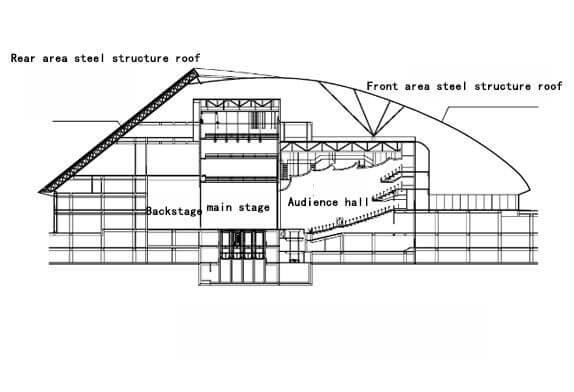

The total construction area of the Silk Road International Culture and Art Center in a consulate area is about 149,000m², which consists of four building units: a grand theater and a multi-functional hall, an art museum, and a government affairs center. The Grand Theater is the core building. Its functions are mainly musicals, operas, songs, and dance dramas. It has a theater with 1345 seats. Its shape is ribbon-shaped, with 5 floors above the ground and 2 floors underground. The height of the highest point of the building is about 37m. The plane size of the main stage is about 31m×21m. The main stage is 10m high and 16m wide. The main stage is equipped with 4 lifting platforms for performances. The side stage is 21m deep and 18m wide. demand. The stage machinery includes the main lifting platform, the orchestra lifting platform, the side trolley platform, and the space frame on top of the main stage, etc.; the auditorium of the theater includes a pool seat on one floor and a balcony on two floors. The overall effect of the building and the section of the building is shown in Figure 1 and Figure 2.

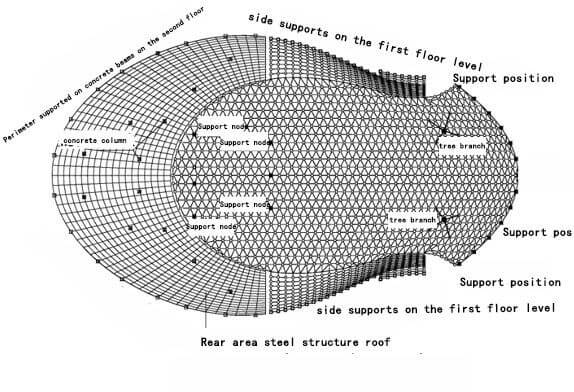

FIG.1 Modern Roof Structure Design of Grand Theatre

FIG.2 Grand Theater Building

The main project of the Grand Theater adopts a reinforced concrete-shear wall structure, and the roof shell and the large-span part of the main stage to adopt a space steel structure system. The roof shell adopts the structural form of a combination of single-layer and double-layer large-span reticulated shells. The seismic fortification intensity of the project is 8 degrees, the design basic seismic acceleration is 0.20g, the site category is II, the design earthquake group is the second group, the characteristic period is 0.40s, and the seismic fortification category is B (key fortification category). The safety level is Class I, and the foundation design level is Class A.

The structural design includes two parts: the leading concrete and the steel roof. This article only introduces the structural design of the steel roof of the Grand Theater. The steel structure of the roof of the Grand Theater is divided into two parts: the steel structure roof of the rear area and the steel structure roof of the front area. They are separated by setting 150mm wide structural deformation joints and become two independent structural units. The steel structure roof of the rear area adopts a double-layer arc-shaped quadrangular pyramidal reticulated shell structure, and the steel structure roof of the front area adopts a combination of a double-layer reticulated shell and a single-layer reticulated shell. Setting up long structural joints can not only meet the requirements of architectural shape connection but also greatly reduce the additional stress of reticulated shells caused by temperature changes.

The lower chord supports of the double-layer arc-shaped quadrangular pyramid reticulated shell of the steel structure roof in the rear area are all connected by hinges. The floor part is supported on the 2-story concrete frame beam, and the middle part is supported on the top of the concrete frame column. The frame beam size is 500×1000, the frame column size is 1000×1000, and the concrete strength grade is C40. The maximum short span of the reticulated shell is 25m, the height is 1.8m, and the space frame size is between 1.8 and 2.1m. The support joint between the roof steel structure and the lower concrete structure adopts a flat-hinged support. When the steel structure is independently calculated, the rigidity of the lower concrete is fully considered and the support is set as an elastic support. The support stiffness is determined according to the stiffness of the joist or cantilever column. The corresponding equivalence is obtained.

The steel structure roof of the front area is relatively complex, the glass roof adopts a single-layer reticulated shell, and the side steel structure adopts a double-layer reticulated shell. The single-layer reticulated shell of the glass roof is supported on the side of the double-layer reticulated shell through connecting rods, the middle part is supported on the lower concrete floor or structural columns through a series of branch columns, and the east side is supported on the 2-story concrete ring beam. The maximum span in the middle reaches 36m. The roof steel structure material uniformly adopts Q345B. The cross-section of the single-layer reticulated shell is □400×200×6×6, and the connection between the single-layer reticulated shell and the double-layer reticulated shell is made of a 500×10 round steel pipe to facilitate mutual connection. The main tubes of the two branch columns in the front hall are made of steel pipe concrete columns, which are directly rooted in the foundation. Through weld connection. See Figure 3 for the plane layout of reticulated shells.