+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

3.3.In the case that the large ball cannot be adjusted, it should be adjusted manually in the secondary design, and the length and size of all the members on the node will be increased accordingly. Among the two members with small Angle, one of the members with the smallest force will be connected by the ball or connecting steel plate. The processing and welding of the ball handle are done in the factory. The material of the ball handle is 45# steel. The end face of the ball hole of the bolt ball is cut normally, and only the smaller process light hole is drilled. The small end of the ball is matched with the ball process light hole, and the ball body is processed into an inclined plane, and the corresponding bolt hole is processed. The length and slope of the knob were calculated.

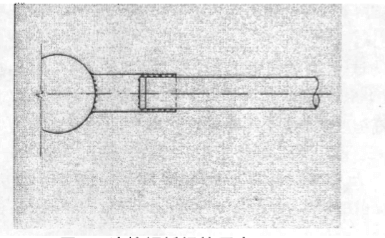

3.4. If the connection of the welded steel plate is used, the end face of the rod hole on the bolt ball is not processed, and only a small marking hole is drilled. One end of the connecting plate is processed with the R concave arc consistent with the sphere, and welded with the sphere at the marked hole position, and the other end is welded with the rod. The dimensions of each part are determined by calculation to achieve the purpose of not touching the adjacent rod (FIG. 3).

Figure 3 Welding diagram of connecting steel plate

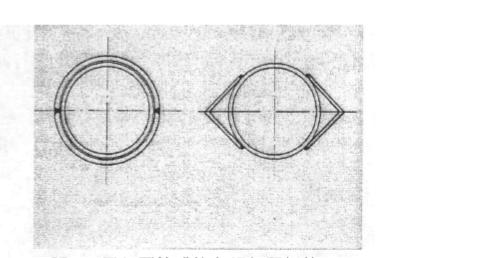

Figure 4. Reinforcement of the rod members with circular pipe or Angle steel

3.5. Irregular reference roof support welding, bridle road and other no support process hole, are on-site welding treatment.

4Precautions for on-site welding

4.1. Everyone is worried about welding. The welding of the ball handle is carried out in the factory, and the welding of the same base material is carried out according to the conventional process, which is no problem. On-site welding, such as the welding of the rod connection plate, the welding of the roof, the horse way, the lamp bridge and other supports, and the welding of the reinforcement parts when the space frame is reinforced, etc., is performed after the installation of the space frame or in the process of using the space frame. Welding site people have three concerns: one is in the space frame members after welding heating will be the internal force changes, resulting in structural instability damage; The second is whether it is possible to weld the steel plate of Q235B and the bolt ball of 45# steel with different base materials; Third, after the component welding temperature, especially on the bolt ball welding will cause high strength bolt annealing and strength reduction.

4.2.The first thing to solve is the problem of welding temperature. When welding, the welding current should be reduced, small specifications of the electrode, do not focus on welding. Break welding and symmetrical jump welding are adopted. Its purpose is to prevent high welding temperature, to achieve sufficient cooling. Because of discontinuous welding, the temperature is fast, so it will not have too great an impact on the stress state of the space frame members. For example, when the pressurized rod is reinforced, it is generally a large steel pipe outside the rod, or two Angle steel welded (see Figure 4), the weld is symmetrical, the welding is broken, the interval is 30cm, the welding is 5cm, and the welding is symmetric, left and right and back and forth, so that the rod will not overheat and the problem occurs.

4.3.Can the connecting steel plate of Q235B and the bolt ball of 45# steel be welded 45# steel is not easy to weld but not equal to welding, if it is like welding Q235B choose E43 type low carbon steel electrode, current is AC and DC, positive and reverse connection, in the case of low temperature, the sphere is not preheated, after welding the sphere must have a crack, with a hammer can be torn off a piece of the sphere. The correct way is to use E50 type low hydrogen medium carbon steel electrode, DC reverse connection, sphere preheating 200℃ after welding, pay attention to take measures to reduce the welding temperature and full heat dissipation.

4.4.What everyone is most concerned about is whether welding on the bolt ball will cause the annealing of high-strength bolts in the ball body to reduce the strength? First of all, find out how much temperature the high strength bolt reaches to produce annealing. The critical annealing temperature of high strength bolts with different materials is different. The following table lists the annealing critical temperatures of three materials of high strength bolts at three strength levels.

|

Strength grade Temperature |

20MnTiB |

35VB |

46Cr |

|

8.8S |

470℃ |

550℃ |

600℃ |

|

9.8S |

440℃ |

500℃ |

550℃ |

|

10.9S |

410℃ |

460℃ |

520℃ |

It can be seen that 40Cr alloy structural steel material is still very good. As long as we take the corresponding process measures to control the welding temperature, the strength of high strength bolts will not be reduced. Two high-strength bolts are screwed into two adjacent M20 holes with Φ120 bolt balls, and hexagonal sleeve and sealing plate are normally set on the bolts. Then a 10mm thick steel plate is welded in the middle, and welding is carried out according to the above process. After cooling, the two high-strength bolts were tested. After testing, the hardness of the screw part was not reduced, and then the destructive tensile test was carried out, and the destructive tensile force of the two bolts was 268KN and 297KN respectively. M20 high strength bolt, 10.9 grade, tensile ultimate bearing capacity of 255~304KN. Obviously, as long as the corresponding welding process is adopted, the sense of responsibility is strengthened, and the welding is carried out on the bolt ball, the high-strength bolts in the ball will not be annealed and the strength will be reduced.

Bolt ball joint space frame, in the site construction or in use, due to various reasons need to dynamic welding, as long as the strict compliance with the corresponding technical procedures, strengthen the sense of responsibility, take seriously, careful construction, is not a threat to the safety of the structure. Can welding but not at will welding, in the absence of other effective measures, only take welding.