+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1 Project Overview

The surface elevation of the steel truss giant vault of a gymnasium in Inner Mongolia is 129.000m, and the maximum span is 322.65m. The structure has a considerable dead weight and many rods. If the conventional high-altitude bulk plan is adopted, a large number of high-altitude scaffolding needs to be set up, which has not only a huge workload of high-altitude assembly and welding but also has a large quality and safety risk. And the construction period of the whole project will have a significant impact, the technical and economic indicators of the scheme are poor, using hydraulic synchronous lifting construction technology to install a steel structure giant arch, can effectively solve the above construction problems, construction speed, high efficiency, good economic benefits. The installation effect of the steel structure giant arch is shown in Figure 1.

FIG. 1 Installation effect of steel structure arch gymnasium roof

2 Hydraulic synchronous lifting technology to lift the giant arch

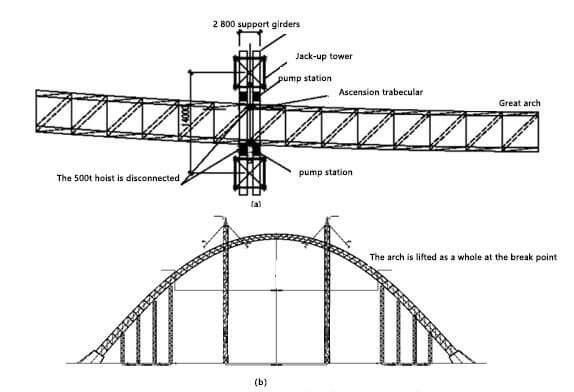

Hydraulic synchronous lifting technology is adopted to lift the giant arch. Two pairs of jack-up towers should be set on both sides of the giant arch, a lifting platform should be installed on the top of the tower, and multiple hydraulic hoists and related lifting equipment should be configured. The elevation layout of the lifting tower is shown in Figure 2(b). Two lifting points are arranged on each pair of towers, altogether four lifting points. Each lifting point adopts two TJJ3500 hydraulic lifters, and the lifting platform is shown in Figure 2(a). In order to prevent the collision of the connecting rods of each unit of the giant arch in the process of lifting, when the giant arch steel structure is assembled on the ground, some of the rods are not installed first and can be installed after the giant arch is raised to the design elevation. After assembling the ground giant arch steel structure, hydraulic lifting can be carried out on the giant arch steel structure.

Figure 2 a(Lifting platform) and b(elevation layout of giant arch steel structure hoisting tower)

3 Hydraulic synchronization

The project adopts hydraulic synchronous lifting technology of large components to install giant arch steel structures. The specific advantages are shown in the following aspects:

1) The giant arch is divided into units on the ground for the overall assembly, the main assembly, welding, and painting processes on the ground, without hindering and affecting other professional construction, high installation efficiency, and quality can be guaranteed, but also can greatly reduce the workload of tower crane lifting, saving the installation period.

2) “Super large component hydraulic synchronous lifting construction technology” hoisting steel structure, mature technology, successful engineering experience in China, can fully ensure the safety of component hoisting; Through the whole hydraulic lifting and lifting of the giant arch steel structure, the overhead work is minimized, and the absolute time of the hydraulic lifting operation is short, which can effectively ensure the installation period of the giant arch steel structure.

3)Hydraulic synchronous lifting equipment and facilities have small volume and mass, strong maneuverability, and convenient reverse transportation and installation; Using the lifting tower can reduce the workload of the crane, and the site is less affected when disassembling; Hydraulic synchronous lifting method has smaller dynamic load during installation, greatly reducing the number of temporary facilities and saving engineering costs. The giant arch hydraulic lifting principle and installation method are to take the hydraulic lifting device as the main lifting equipment, for the core piercing structure; It is reliable, safe, light, and no lap joint to lift the bearing members by steel strand. The two sets of wedge-shaped anchors at both ends of the hydraulic hoist are unidirectional self-locking. When the anchor is clamped, the strand is locked; When the anchor is released, the strand is released and can move up and down. The whole lifting process is a set of flow of hydraulic hoists.

4 Hoisting tower installation

4.1 Tower Installation Two pairs of self-climbing towers are arranged according to the giant arch structure roof, and one 20T crane is arranged on the top of each pair of self-climbing towers. Both sides of the huge arch are arranged to lift the door frame, the distance between the two door frames is 90000mm, the center distance between the tower of the door frame is 14m, and the height of the door frame is about 130m. The elevator is installed on the steel beam of the portal frame and is connected with the lifting point of each unit of the giant arch through the steel strand. The lifting is divided into several stages, and each stage is synchronous lifting. The installation quality of the tower reaches 5000T, and the lifting height is 102m. The tower assembly adopts a self-climbing installation, which can realize self-lifting and self-lowering without a large crane installation. The tower installation height is 126m. After the top-up of the tower is completed, the permanent cable and wind rope shall be laid, and the short beam shall be hoisted to the main beam. Finally, four 350T hydraulic lifts are arranged on each of the two pylons.

4.2 Tower Cable Wind ropes Are arranged to stretch the cable wind stabilizing cables at the top of the tower portal frame to ensure the connected state of the top of the tower and balance the horizontal wind load. The center distance of the two secondary towers is 90m, and the center distance of the door frame of each secondary tower is 14m. Since the wind ropes of the main and secondary cables are both pulled on the two small arches beside them, and the small arches themselves also need cables, and their force is more than 1000kN, it is not considered to set another cable, among which the force of the main cable is 400kN. The force of the secondary cable wind rope is 600kN.

5 Giant arch installation

5.1 Segmented installation method of a giant arch

The whole steel structure will be divided into 5 units, the units at both ends of the assembly bracket and crane auxiliary assembly, the rest of the hydraulic synchronous lifting and lifting, and the middle 5 units are assembled on the ground; First of all, a middle unit 4 assembled and rose to a certain height, then the middle units and 5 units 3 and 4 unit connection and installation as a whole, will be three units upward, rose to a certain height, will be 2, 6 units and 3 units, the whole body, connection, and installation into 5 unit as a whole, to enhance 5 units, rose to the position design, with 1 again, The 7 units are connected and installed into the final whole of 7 units, and then the reserved post mounting rod is installed in turn. This installation method reduces the tedious to simple, reduces the difficulty of installation, and ensures the installation quality and progress.