+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

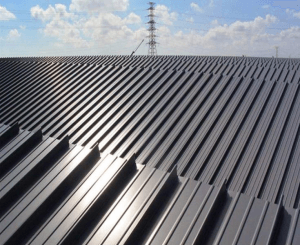

We all know that the anti-corrosion performance of roofing materials directly affects the waterproof, aesthetic and durable functions of the roof, especially the anti-corrosion performance of roofing panels, which is also related to the service life of the roof.

Aluminum-magnesium-manganese metal plate

Aluminum-magnesium-manganese metal plate is very popular in recent years, there are also a lot of publicity online that durable, then, in the end, how many years it can be used, how can you extend the service life of the roof? Let’s analyze it together.

Houses use galvanized, aluminum-zinc or resin as roofing panels, and their substrates do not have any anti-corrosion ability. As a result, the decorative parts of the pressurized steel roofing and screws will rust quickly due to the lack of coating protection, and the protective layer on the surface may be damaged in many parts of the production, loading and unloading, transportation, installation, and so on. Resulting in its localized corrosion Once localized corrosion occurs in the pressurized steel plate, it will gradually spread, affecting the aesthetics and waterproofing of the roof.

Aluminum-magnesium-manganese metal plate

And the aluminum-magnesium-manganese plate is made of excellent aluminum-magnesium-manganese alloy material, and its substrate has strong corrosion resistance, especially in the acidic environment, and its corrosion resistance is much higher than that of the steel plate and ordinary aluminum alloy plate. According to the relevant standards, its service life in ordinary environment is not less than 50 years. The environment is good because the bottom layer is covered by the roofing sheet, which is not eroded by wind, rain and sunshine. Considering economy and applicability, the screws used in the roofing system are all excellent screws and the fittings are all excellent aluminum alloy fittings. Therefore, the roofing system, from the roof panel, the underlying floor slab to the screw purlins and fittings, has good corrosion resistance, thus ensuring that the service life of the whole roofing system will not be affected by the weakness of a certain part of the system.

What’s more, aluminum-magnesium-manganese panel adopts vertical locking edge fixing method, and the aluminum alloy fixing seat is only limited to the movement of the roof panel in the direction of width and up and down, but not the movement of the roof panel in the direction of length, therefore, when the temperature changes, it can be free to expand and contract on the fixing seat without generating temperature stresses. This helps to solve the problem of temperature deformation, which is difficult to overcome with other panel types, and ensures solid roof performance. In addition, at the roof openings and at the connection between the Al-Mg-Mn sheet and the skylight, the nodes can be fastened with welded flashing, so that the roof panel is still free to expand and contract without constraints at these places.

It can be seen that the life of the roof is not only due to its construction materials, but also the method of installation.