+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The rock wool sandwich panel for the outer wall of the steel structure is made of color-coated steel plate (or aluminum-magnesium-manganese alloy plate, stainless steel plate, plated metal plate) as the surface layer, with non-combustible material rock wool as the core material, and two-component polyurethane adhesive It is a cementing agent, which is formed by continuous heating and pressing, and cut to length synchronously. It is a multi-functional exterior wall building board that integrates heat preservation, energy saving and decoration. Pressure, sound absorption, sound insulation and other aspects have significant effects. With the development of color, appearance, and thickness diversification, rock wool sandwich panels have become the preferred building materials for green, healthy, and artistic buildings.

1.Project overview

The design requirements for the exterior wall of the steel structure factory building in the Liujian Industrial Park of Hunan Construction Industry are that the exterior wall is more than 1200mm, and the outer panel is 50mm thick bidirectional rock wool sandwich panel (horizontal installation), and the panel is 0.55mm thick fluorocarbon coated color Steel plate, the middle layer is 50mm thick rock wool, the bottom layer is 0.45mm thick single-layer color steel plate (white), the main specification is 6000mmX900mm, the yield strength is 3345MPa, the surface layer is galvanized with more than 150g/m2, and the rock wool density is 100kg/m2 m3; The inner side is additionally equipped with vertical strips with a vertical interval of 1500mm, and the inner wall is made of 0.45mm thick YX15-225-900 vertical white-gray color steel plate.

2.Structural form and horizontal installation characteristics of rock wool sandwich panel

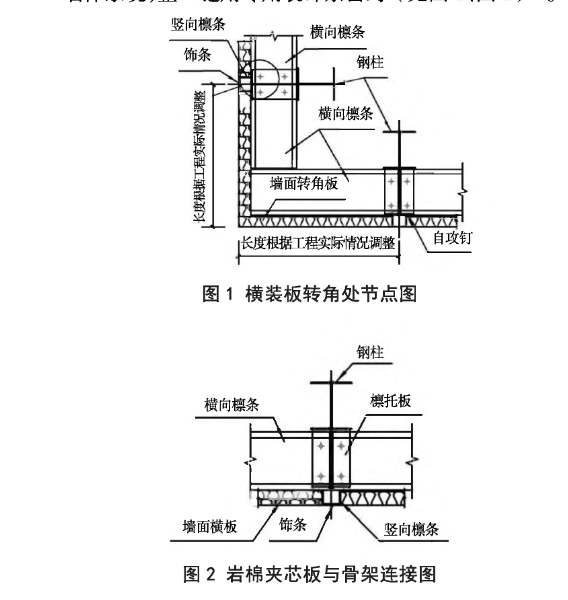

2.1 Structural form The rock wool sandwich panel is connected by a tongue-shaped bite groove at the tongue and groove, and the hidden screw is fixed with the substructure of the label. The wall system is composed of the sandwich panel and the substructure, and the tongue and groove joint is sealed with a special decorative strip (See Figure 1, Figure 2),

2.2 Features of horizontal installation

(1) High-density rock wool and high-quality steel plates are used to ensure the mirror flatness of the sandwich panel, and there will be no drumming or delamination on the surface of the 6-8m long plate.

(2) The rock wool sandwich panel is installed horizontally and fixed with hidden hidden nails. The upper panel covers the lower panel through a tongue-shaped bite-and-groove connection, and special decorative strips are used for the tongue-and-groove joints. There are no drilling holes on the surface, and it has an exclusive waterproof structure and is sealed with structural adhesive, which solves the hidden danger of water leakage, and the building wall is beautiful and smooth, prolonging the service life.

3.3.Rock wool sandwich panel horizontal installation construction process

The installation of the main steel structure is completed and the verticality is corrected – wall marking strip installation T wall trimming support bracket welding – sheet material cutting, transportation and entry – initial board installation – sandwich panel and door and window trimming installation F strip and Waterproof construction.

4.Key points of rock wool sandwich panel horizontal installation

4.1 Preparations before construction

Technical preparations.

①According to the approval drawing and board type confirmed by the design institute, combined with the door, window position and on-site purlin support plate spacing retest data, use BIM technology to typeset the vertical marking strips on the wall, the specifications of the horizontal mounting boards, and the patchwork trim , establish a three-dimensional model, determine the form of trimming, and issue a layout drawing. At the same time, BIM technology is used to digitally model the starting position, and the starting elevation of the wall panel is accurate to ensure installation accuracy and facade effect.

②According to the design requirements and structural drawings, make a layout plan of the sandwich panels on the wall, and indicate the number, specifications, dimensions of the panels and the connection positions with the steel structure wall purlins, columns, doors and windows on the layout drawing.

③Before installation, organize the construction personnel to conduct safety technical disclosure, and clarify the horizontal installation standards and control points of rock wool sandwich panels.