+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

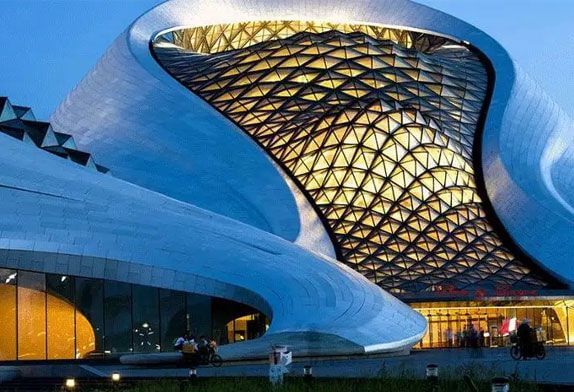

The main steel structure hall can accommodate 1564 people, and the small theater can accommodate 414 people. The total hall construction area is about 79396m², and the maximum height is about 56.48m. The magic of the whole architectural design is that the backstage adopts a full glass lighting roof design, which can not only bring natural light into the room but also the outdoor natural scenery as the background of the performance so that the performance, nature, and audience are integrated, blurring the feeling of indoor and outdoor.

Figure 1 glass daylighting roof for hall

The glass roof system of the hall is mainly composed of a metal roof with vertical locking edges and a four-pyramid glass daylighting roof. The waterproof level of the roof is level ⅱ, and the reasonable service life of the waterproof layer is designed for 15 years.

2.1 Design of glass lighting roof and sheet

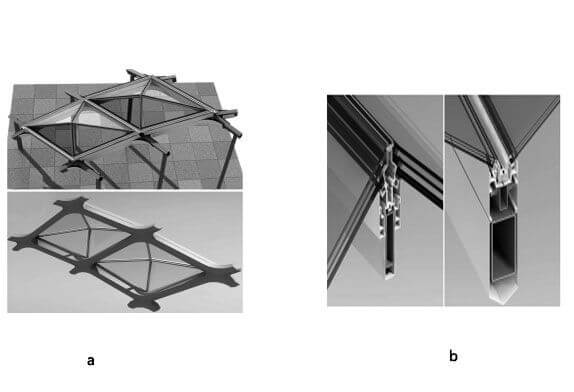

The lighting glass roof is composed of diamond-shaped monomers, each of which is a perfect pyramid (Figure 2). However, because the skylight as a whole is a three-dimensional curved surface, this leads to the subdivision of the unit on the axis of symmetry, the other four pyramids are different. The unique shape and thermal insulation requirements of the building posed no small challenge to the design and installation of the roof.

Figure 2 glass roof system a(Effect diagram of pyramid glass lighting roof) and b(Effect of pyramid frame)

Pyramidal glass is made of two right triangles, each of different sizes. In order to meet the final splicing effect of the special-shaped surface, the glass adopts the design of large and small pieces (that is, three glass pieces of a single insulating glass have different sizes) to meet the needs of the waterproof and sealing structure of the system.

2.2 Support space frame design of glass lighting roof

The lighting glass roof system is composed of steel keel, aluminum alloy cushion frame, galvanized steel adapter, aluminum alloy adapter kit, aluminum alloy sub-frame, aluminum alloy gusset plate, glass panel, and other material components. The steel grid structure is adopted, and the glass panel is connected to the node of the main structure by the transition system. The conversion system is composed of two round pipes with thread and 8 groups of connecting lug plates. The two round pipes are connected by a thread. The 8 groups of connecting lugs are welded to the round pipe located at the top according to the installation Angle of the steel keel of the lighting roof, and the round pipe located at the bottom is connected to the node of the main steel structure grid during installation. The transfer system can adjust the horizontal (tilt) direction, vertical direction, and in-plane installation Angle of the steel keel of the daylighting roof, and adapt to the requirements of various installation angles of the glass plate of the daylighting roof system.

Each four-pyramid steel keel is composed of 4 cone bottom frame and 4 cone edge frame, a total of 8 keels, keels are made of galvanized square steel tube; Two keel end plates are welded at both ends of the cone bottom frame keel, and then the lug plate is welded on the keel end plate; One end of the conical edge frame connected with the adapter is welded to the keel end plate, and then the lug plate is welded to the keel end plate, and the other end is welded together to form a cone tip according to the composition Angle of the four pyramids. The cone bottom frame is respectively connected with the corresponding adapter through stainless steel bolts; the Conical edge frame is also connected with the corresponding adapter through stainless steel bolts.

Aluminum alloy pad frame, aluminum alloy conversion kit in turn by tapping nails, bolts, pressure plate connected to the pyramid edge frame, aluminum alloy frame, and glass panel assembled together by silicone structural adhesive. The aluminum alloy subframe is designed with an arc mounting groove matching the adapter suite, and the adapter suite is designed with a circular arc mounting convex head. The glass panel is hinged with the arc mounting convex head on the adapter suite through the arc mounting groove of the aluminum alloy subframe.

2.3 Waterproof and sealing design of glass lighting roof

In this project, the glass lighting roof adopts a hidden frame structure to reduce the use of exposed aluminum profiles. A small amount of exposed aluminum profiles are connected with heat insulation materials, which cut off the cold bridge, improve the thermal insulation performance of the lighting roof system, and avoid condensation on the surface of the profiles. The glass panels are sealed with high modulus silicone sealant, which can meet the expansion deformation of the glass plate joints under the temperature difference of 80℃, so as to ensure the waterproof sealing performance of the lighting roof. Aluminum gusset plates are used to decorate the main structure and the outer steel keel of the daylighting roof, which not only has a good decorative effect but also improves the corrosion resistance of the system.

The lighting roof has a large tilt Angle to ensure that the roof does not accumulate water, and the rainwater can be discharged to the drainage gutter around the roof through gravity. The concrete method is as follows: aluminum veneer is used to make a flood plate at the junction of the lighting roof and vertical lock plate roof system; The flooding plate is fixed by pressing the plate, and the glass joint is sealed by a sealant. The other end is extended to the vertical side lock plate around the gutter, and the roof rainwater is quickly discharged into the drainage system.

Hall project is a landmark building in Harbin, built by water, consistent with the design style and positioning of Harbin Cultural Island, reflecting the design concept of the northern landscape. The project glass lighting roof adopts a double-layer hollow glass pyramid shape hidden frame, hidden frame design will completely isolate rain on the outdoor side, with a reasonable drainage system design, to ensure the waterproof function of the whole roof system.