+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The space frame structure is a high-order statically indeterminate spatial structure, which has good spatial stiffness and integrity. Under the condition of uneven settlement, the space frame structure can also overcome the adverse effects by using its own stiffness and integrity. At the same time, the weight of space frame structure is light with less steel. Its structure can meet the needs of the aesthetic of modeling, and it can better reflect the rational design thought, especially suitable for large-span public buildings.

The structural layout should not only meet the stress requirements of the structure but also meet the requirements of economic rationality, and also meet the requirements of the architectural profession for its use. There are many types of space frames. It can be divided into a cross truss, quadrangle cone system, and triangular cone system. The cross trusses can be divided into five types: bidirectional orthogonality space frame, bidirectional orthogonality diagonal space frame, bidirectional diagonal space frame, tridirectional space frame, and unidirectional folded space frame. The tetragonal cone system can be subdivided into square tetragonal cone space frame, deflated tetragonal cone space frame, checkerboard tetragonal cone space frame, and diagonal tetragonal cone space frame and star tetragonal cone space frame. The subdivision types of triangular cone systems are relatively few, mainly including triangular cones, evacuated triangular cones and honeycomb triangular cones. The space frame can also be classified according to the number of layers of the chord. General engineering projects use single-layer space frame, heavy loads and other special requirements can increase the number of layers of the space frame and can use 3 or even multi-layer space frames. However, due to a large number of member layers and the complex node structure, the cost of this space frame is also high.

The middle span of the roof of the comprehensive transportation hub project is 26.1m, the cantilever on both sides is 13.1m, and the longitudinal column spacing is 26.1m. Firstly, the plane form of the transfer hall is selected according to the characteristics of span, load, and column distribution. The column layout and space requirements determine the form of point support. As the span of the two direction trusses is close, the force of the two direction trusses is relatively uniform. Under these conditions, Two square tetragonal cones can interact with the whole space and have good mechanical characteristics. Therefore, the project uses the lower chord point to support two orthogonal square pyramid space frame.

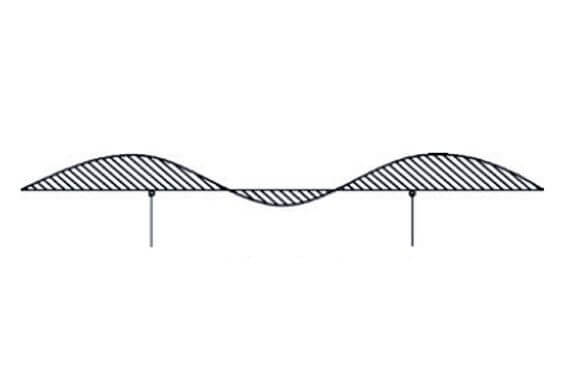

Then determine its profile form and draw its bending moment according to the support conditions of the space frame, as shown in FIG. 1.

FIG. 1 Overall bending moment of the space frame section

According to the bending moment diagram, adjust the height of different positions of the space frame structure to achieve the best stress and economic effect. The average height-span ratio of the space frame is 1/10~1/8, and the height of the space frame is thickened at the bearing part with a larger bending moment. Combined with the requirements of professional architectural modeling and water supply and drainage for roof drainage, the surface of the space frame presents a low bearing position. Curved form with high sides. The primary section of the structural layout is shown in Figure 2.

Figure 2 Preliminary layout of the space frame section diagram

According to the selected model, it was found that the deflection at both ends did not meet the requirements of the 1/125L specification after the section as shown in Figure 2 was selected. Analysis of the reasons, although the section form and the size of the bending moment fit, the middle height of the structure is small, so the structure has a large deflection at both ends. Accordingly, the middle part of the structure is thickened, and the optimized section is shown in Figure 3.

Figure 3 Finally determine the space frame section diagram

The large-span cantilever steel space frame roof of the comprehensive transportation hub adopts the following analysis scheme. Firstly, a simplified bearing model is used to design the member. After the design is completed, an accurate and meaningful overall analysis is carried out. The calculation of the member with simplified support is carried out in professional design software (such as MST, SFCAD, etc.). In this case, the support stiffness can be input by the simplified method in Appendix K.04 of JGJ 8-2010 technical Specification for Spatial Grid Structures. The rubber bearings, columns, and beams all affect the bearing stiffness of the space frame. Therefore, the bearing stiffness is mainly composed of two parts :(1) the stiffness provided by the narrow sense bearings such as the rubber bearing of the space frame and the ball hinge bearing; (2) the stiffness provided by the substructure of the space frame, such as concrete column, steel-concrete column or the generalized support such as rack and steel frame. The rigidity of the narrow bearing can be obtained by the formula provided in the specification or the product parameters provided by the manufacturer. However, the stiffness of the lower generalized bearing is difficult to be obtained by a simple calculation. At this point, the finite element model of the structure can be established by using finite element software and obtained by applying unit force in the specific direction of the top of the column.

The design of a large-span cantilever steel space frame is different from that of an ordinary steel structure, but as long as we grasp its characteristics and solve the problems caused by its specificity, we can complete its design smoothly and with high quality. The following conclusions can be obtained from the summary.

(1) It is very important to rationally arrange the structure of the large span and long cantilevered space frame. Due to the existence of the cantilevered end, it is often necessary to increase the height of the middle part to increase its bending stiffness to reduce the deflection of the cantilevered end.

(2) In the design of the space frame structure, it is necessary to carry out the design of the rods and the overall analysis of the structure of the space frame and the support system.