+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

4 Component approach and site

Before unloading the stacking grid components, check the design drawings and the manufacturer’s delivery list to check whether the rods, node balls, supports and the spare parts required for grid installation are incomplete, and feedback to the manufacturer in time if there is any problem. For component stacking requirements and protection, the following requirements must be complied with: The stacking of finished products generally requires that the component stacking site should be flat, solid, dry, and have drainage measures. Components should be stacked stably and the supports should be flattened. For multi-layer horizontally stacked components, the components shall be separated by skids, and the skids of each layer shall be placed on the same vertical line to ensure that no deformation occurs during stacking. During the stacking and lifting process of the components, no holes shall be arbitrarily opened on the components or any rods shall be cut off, and no impact shall be suffered. Components with a high center of gravity should be placed on temporary supports, or tied firmly against the columns to prevent damage from falling.

5 embedded parts pre-embedded

Before the construction of the project, it is necessary to carry out repeated technical disclosure, familiarize yourself with the drawings, specifications and relevant regulations. The role of embedded parts is self-evident, and it plays a role of linking the past and the future. The embedded parts themselves require accurate positions, and the reinforced concrete structure requires the combination of embedded parts, concrete and steel bars to meet the requirements. This is a necessary condition for the normal use of embedded parts. To realize the accurate position of the embedded parts, firstly, the embedded parts must be placed accurately, and secondly, the embedded parts must be reinforced firmly. During construction, pay special attention to the lofting of embedded parts, the cleaning and protection of embedded parts, and the positioning of embedded parts to ensure their use functions. The embedded parts of the space frame are pre-embedded when the steel nail formwork is bound before the concrete structural column is poured, and the lofting is carried out first, and the position of the center and axis of the column top and the elevation position of the embedded parts are marked. Embedded parts should be embedded according to the specifications to control several parameters, such as the elevation, inclination and axis offset of the embedded parts. These deviations should meet the specifications and time requirements. The protection of embedded parts is a tricky job. Due to the cross work of multiple types of work, the embedded parts may be damaged or shifted. Therefore, in the process of steel formwork installation and concrete pouring and tamping, special personnel must follow the whole process and vibrate the concrete. It may cause the deviation of the embedded parts, adjust it back to the allowable range of the specification before the initial setting of the concrete and make a record in time.

6 grid installation

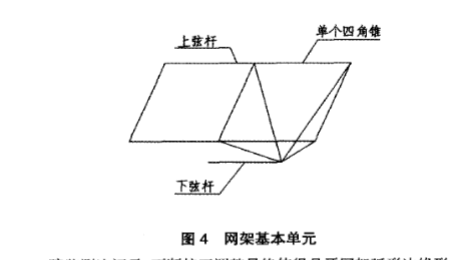

Starting from the middle support, it can be installed to the two ends of the crescent shape respectively. Only install the members within the vicinity of the support. The installation method is as follows: the first step is to install the lower chord and the ball, according to the number of the installation drawing, pad the plane of the lower chord ball, connect the lower chord with the ball and press it into place at one time. The second step is to install the web bar and the upper string ball. The web bar and the upper string ball should form a downward quadrangular cone. The connection between the web bar and the upper string ball must be tightened in place at one time. Install the top chord lifter service. The third step is to install the upper chord. The installation sequence of the upper chord is passed from the inside to the outside. According to the above steps, directly assemble a single rod and a single node into the basic unit of the network frame and put it upside down. The quadrangular pyramid (see Figure 4). During the assembly process, the position of each node should be measured and checked, and the installation of the network frame at the back No displacement occurs during the process, the offset of the grid node center is not greater than 1.5mm, and the length of the single-cone grid is not greater than +1.5mm. First assemble the rods around the center support to form a small piece of unit. You can position according to the ink line on the embedded part and initially fix the grid support, and spot weld the support with electric welding. In this way, the starting unit is installed step by step. After the grid installation of the starting unit is completed, self-inspection is carried out immediately to ensure that the padding of the lower string ball, the accuracy of the axis, the tightening degree, deflection and Geometry. Assemble simultaneously in two directions with the starting unit as the center. According to the design drawings and the deflection or deformation control points selected by the project team after research, mark them well, record them while tracking and monitoring them, and constantly correct and adjust them to finally make the curved edges of the crescent grid form a whole, and observe the deflection and deformation of each control point The displacements are all within the allowable range of the design. General process of installation process: Pre-check the axis and elevation of the support – measure the control line – install the support node – assemble the lower chord of the space frame – assemble the upper chord of the space frame – fasten the node bolts – check the bolts in place – tighten Fix the anti-slow screw, check the screw in place, and repeat the above work.

Although this project has a special-shaped structure, the installation method is basically the same as other grid installations. The key processes of installation, the installation method, the installation partition and the installation direction are determined.