+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

With the development of science and technology, the construction industry has also accelerated its pace and entered a new stage. Long-span steel structure is a relatively cutting-edge construction technology, which is widely used and developed rapidly in various countries around the world. Compared with some developed countries, China’s long-span steel structure technology started a little later, but its enthusiasm is not lost to other countries. As early as 2008, my country used long-span steel structure technology to build the Bird’s Nest and Water Cube, which became landmark buildings in my country’s construction industry, which made China’s construction industry take a huge step forward and had a huge impact both at home and abroad. With the continuous innovation of the times, the technology of large-span steel structures needs to keep pace with the times and update and progress. Based on the actual project, this paper studies a construction method of long-span spherical space frame, and conducts an in-depth analysis of the construction technology of large-span spherical space frame structure.

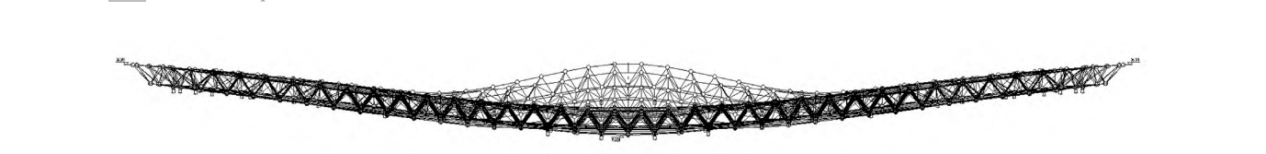

The construction project of Jingpeng No. 1 Middle School Gymnasium in Hexigten Banner has a total land area of about 3310m2, a total construction area of 5849.81m2, and a building height of 18.8m. The structure is a reinforced concrete frame structure, and the roof truss structure adopts square cone bolt balls space frame structure; the maximum span of the space frame is about 63m, the main grid size is 3m×3m, and the thickness of the space frame structure is about 2.7m, as shown in Figure 1. The difficulty of this project lies in how to carry out high-precision and high-quality welding of relatively complex nodes. The assembly adopts the method of preliminary ground assembly combined with high-altitude bulk assembly, and accurately assembles various parts on the ground, and then uses a crane to assemble the assembled space frame on the ground. For hoisting operations, the hoisting process and the selection of crane points are more difficult.

Figure 1 Elevation of space frame

2.1 Characteristics of structural materials

The strength of steel has extremely high requirements for long-span spherical space frame structures. Compared with traditional buildings, steel space frames lack the support of beams and columns in traditional buildings. Under the action of load, the shear force will also increase, and the quality of the material itself is one of the important factors to overcome the shear force. Usually, the method of improving the quality of the material itself is to increase the material thickness of the rigid member to increase the thickness and enhance the material strength, but the increase in the thickness brings the increase of the self-weight of the member, which increases the load of the space frame from the weight of the member. Nowadays, with the development of the times and the rapid advancement of science and technology, various new materials have poured into construction projects, among which the comprehensive performance of Q460E steel is relatively prominent.

2.2 Technical characteristics of connection construction

In the construction of large-span spherical space frame structures, the joints are usually welded and bolted. The welded joints are used. During the welding process, the high temperature generated by welding will change the material of the space frame structure, and the weld seam formed by welding may also cause deformation of the spliced parts of the components. Therefore, when the components are connected by welding, It is necessary to make preparations before welding. The length and depth of the weld seam at the welding part can be estimated, and this can be used as a basis for slotting the welding part of the component. The depth of the slot is equal to the depth of the weld seam. When bolting, choose high-strength bolts, the tensile strength of which should be ≥ 900N/mm, and the bolts need to be re-tightened many times.