+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

As global pollution continues to increase, more and more countries are focusing on environmental improvement measures. Open-pit yards storage such as thermal power plants, port terminals, coal mines, coking plants, coal washing plants, cement plants, and iron and steel plants,are extremely harmful to the surrounding environment.

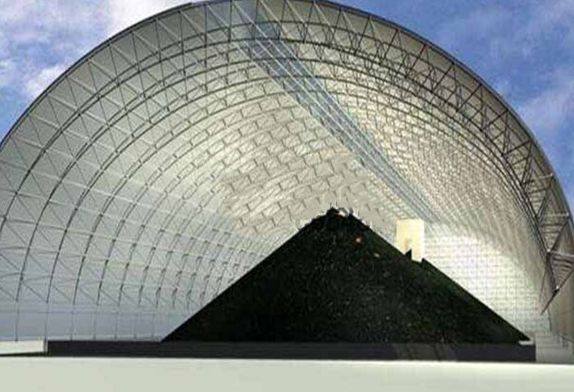

There are two solutions for the membrane structure to close the coal yard and they are as follow: fully closed gas membrane and semi-closed membrane structures.

Fully closed coal yard with inflatable membrane: Fully closed coal yard, long-span coal yard.

Without beams and columns, light weight can reduce civil requirements and costs, thus saving 25-60% of construction costs, and the construction period is as short as 2-4 months. A maximum span of 300 meters can be built, and it can withstand a typhoon of magnitude 16, a magnitude 8 earthquake, and a snow load of nearly 1 meter. Has a complete gas, dust monitoring, emission system and a complete fire protection system. No staff on duty, equipped with a wireless control system to achieve remote control on the Internet. And equipped with professional dust removal and dust reduction measures to ensure that the exhaust is clean, environmentally friendly and free from pollution.

Membrane structure semi-closed coal yard-with train access, semi-closed coal yard.

The construction cost is lower, saving 10-20% of steel compared with traditional color steel plate. The service life is longer, and the service life of the membrane structure can reach 30-40 years (color steel plate 3-5 years). The structure is safer, lighter in weight, and has better earthquake resistance, typhoon resistance, snow resistance, and longer span. The membrane structure span can reach 150 meters. The light transmittance is higher, and the film transmittance is as high as 10-30%, which is more energy-saving and environmentally friendly.