+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

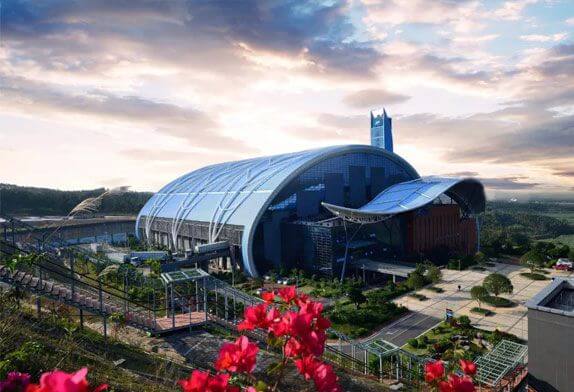

As the Guanzhuang Waste Disposal Plant, a key project in Tianjin, we have paid attention to fully reflecting the advanced production technology in the planning and architectural design of this waste disposal plant. The shape of the roof is very important in architecture. Combining with the overall planning requirements of the site and meeting the process requirements, we used the arched light steel roof in the primary fermentation warehouse and finished product warehouse project. The contrast not only highlights the function and individuality of the single building but also unifies it in the group building. The building highlights the word “new” in both the graphic design and the facade design. The beautiful and unique architectural shape is coordinated with the advanced waste treatment production technology and the outdoor environment and is integrated into the group appearance of the greening, roads, and production indoor and outdoor facilities in the entire site, creating a comfortable work and life for the working and production personnel. The environment allows people who have been there to break the impression of the old appearance of the traditional garbage disposal site in their minds, and can fully feel the strong atmosphere of modern production enterprises. On the main road outside the site, the group buildings in the jumping site are scattered in height, the single building is simple and elegant, the local treatment is delicate, the color of the outer eaves is bright, and the bird’s-eye view effect is extremely remarkable.

The shape of the arched light steel roof is an arc line, which is light and beautiful in size. When the height of the cornice is fixed, the indoor space is increased, which is convenient for the implementation of production and the one-time fermentation of garbage, and the convection of indoor natural wind is increased, and the internal environment quality is improved. The cost of the roof structure in industrial buildings accounts for a large proportion of the entire building, and economic design can play a decisive role in meeting the conditions of application and aesthetics. As the main load-bearing component of the roof – the roof truss, the traditional triangular and trapezoidal angle steel roof trusses are relatively heavy, complex in structure, and troublesome to manufacture, cut and weld.

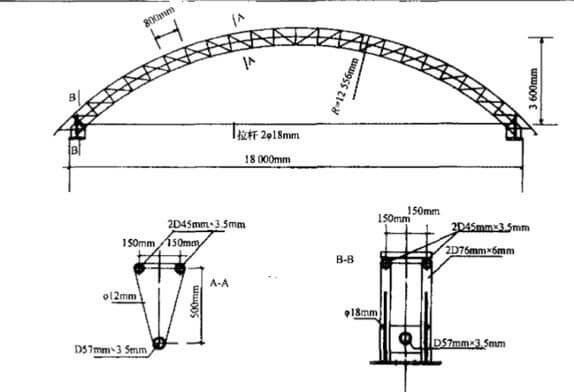

The roof can only be made into a two-slope flat roof, the appearance is rigid and monotonous, and its advantages are mature in design theory and convenient for structural calculation. Our design adopts the arch-shaped space truss type arch beam roof truss, (as shown in Figure 1) the structure is two arches, the arch beam is a triangular section, and 3 round steel pipes are used (convenient to make an arc type), and the round pipes are The inter-web bars are made of round steel bars. The lower chord adopts a horizontal round steel rod (tighten with turnbuckle bolts). Under the action of load, the upper chord arch beam produces a large internal bending force, and the lower chord produces a large tensile force. At this time, the upper chord arch beam is the space section with the strongest compressive bending ability, and the lower chord circular steel bar has the largest tensile capacity. This gives full play to the mechanical properties of each rod. Due to the reasonable stress on the roof truss members, the small internal force of the web of the arch beam, and the short length, the short round steel bars can be fully utilized, and the small materials can be used. The member nodes are directly welded, eliminating all the steel of the gusset plate, the structure is simple, and the manufacture is convenient. Since the arch beam has a triangular section, the out-of-plane stiffness is large, which reduces the amount of steel used for vertical support. The overall roof truss has greater strength and stability, and at the same time reduces the amount of steel used, which can reduce the cost by a quarter compared to the traditional roof truss.

In roof truss end-bearing node design, considering simple production, and reasonable force, the vertical section of the end is rectangular, the four sides are round tubes, and the middle is flat steel, which increases the stability of the node and facilitates the connection of round tubes and tie rods. In order to meet the requirement of seismic design intensity of 7, the upper chord horizontal support, vertical support, and longitudinal wind-resistant column are set up. The top of the wind-resistant column and the arch beam is tied with spring plates so that the roof forms a complete spatial structure system. In order to prevent the roof truss from being compressed by the wind, the in-plane rigidity of the bent column and the tension connection between the roof truss end support and the column top was appropriately strengthened.

The roof panel is made of color composite pressed light steel plate, which integrates heat preservation, heat insulation, and waterproofing. It has the characteristics of beautiful indoor and outdoor, lightweight, corrosion resistance, high strength, fast installation, and so on.

The light steel arch roof not only meets the requirements of the production process but also has a beautiful appearance, good stress performance, saving steel, reduced costs, and convenient construction. Has a unique vitality. Tianjin Guanzhuang Garbage Disposal Plant was completed and put into use at the end of 2000 with good results. However, the lower tie rods of this arched roof truss is relatively soft and can not provide vertical support between the upper chord and the horizontal tie rods, so it is not suitable to use a large-span roof truss in high-seismic intensity areas, and the quality of the rod joints is not easy to guarantee. However, with the continuous improvement of the design structure and the continuous development of the production level, the status of the new light steel arch roof in the roof design will continue to improve.