+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

7、Overall whereabouts

(1)Simulated falling: Before the official falling operation, all personnel will undergo unified training and simulated tests, and special personnel will be assigned to command on site to ensure that the operators on each working face are in step with each other, and the entire falling process is carried out smoothly and orderly. And set up special personnel and special equipment to continuously monitor the vertical displacement and horizontal displacement of the overall space frame.

(2)Formal drop: first drop all the nuts at the bottom of the steel column by 5mm, then drop the diagonal jacks of each steel column by 5mm, and then drop the other two jacks for each steel column by 5mm. Change, the falling speed should not be greater than 10mm each time. The initial landing has static inertia, and it will stop when it falls to 5mm for the first time. Comprehensive inspection again, the position of the jack and the anchorage. if the position needs to be adjusted locally after inspection, the method of jacking pads is used for local adjustment to achieve the purpose of adjustment. The static state reaches 4 to 6 hours. After checking that the structure is normal, land again . After landing, observe closely through the level gauge, if there is no deformation and other abnormal phenomena, proceed to the second landing. If there is any displacement change, use the cable wind device to fine-tune it. After the position is calibrated, repeat the above steps in this way until it falls to the height of the control position.

8、 Welding process and post-processing

After falling to the position of the control point, the steel plates for welding the butt steel columns are welded. According to the requirements of the original design drawings, the joints are all welded with groove full penetration

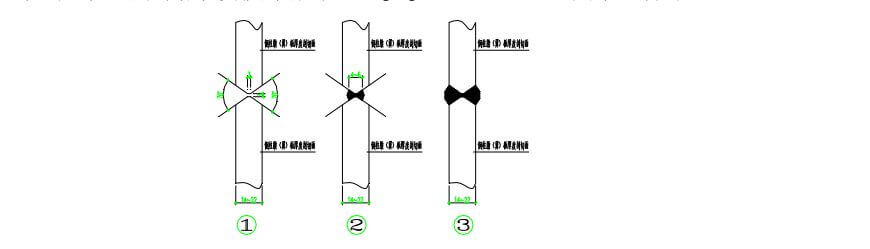

(1)、After the slope is cut, the bottom weld (4-6) mm wide is firstly made. (as shown in the figure).

(2)、Clean up welding slag and flux, then cover welding symmetrically, penetrate the base metal, and make the melting tank full of welding.

(3)、Ultrasonic flaw detection of welding seams has reached the second-level welding seam standard of “Technical Regulations for Welding of Construction Steel Structures” (JGJ81-2002).

Schematic diagram of butt weld construction

After welding, the original welded upper and lower steel plates may not be cut off, as the steel column stiffener (weld joint reinforcement), and the vertical stiffener is welded. Other welded parts are not allowed to disturb the base metal, cut off according to the requirements of the specification, and the cut is polished and painted with anti-rust and anti-corrosion treatment. The bottom of the steel column and the welding position shall be treated with antiseptic treatment or poured concrete column platform according to the construction requirements of the existing canopy.

一、Anti-Tipping Safety Measures

In order to prevent the space frame from overturning as a whole, a support platform is built with heavy-duty steel pipe scaffolding. Each platform is covered with thickened scaffolding boards, and the support platform is set at the load-bearing node position of the support. The landing fulcrum is set around the permanent support position of the space frame. The space frame structure of this project has a total of 6 supports. First, four segmented steel pipe columns are erected around the steel column or scaffolding is set up around the steel column (a steel plate with a thickness of more than 20mm should be added at the bottom (to disperse the jacking concentrated stress). erected with steel pipe scaffolding).

Attachment: fulcrum strength check calculation:

(1)Add all the loads after the space frame is modeled, and carry out the overall force calculation.

(2)Remove the support point, assuming that the two lower string balls adjacent to the support attachment are temporary support points (fulcrums), which only bear downward pressure, and the load is loaded according to the actual situation when the upward force is applied, and the overstressed rod is increased parts or add auxiliary rods. This measure is used as a backup protection measure for this landing construction plan to ensure the safety of personnel and equipment during construction, because the cable wind device installed at the steel column is a reliable guarantee to prevent the steel frame from toppling. In order to ensure the smooth completion of the project, secondary safeguard measures were added.