+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1. Stadium Canopy Project Overview

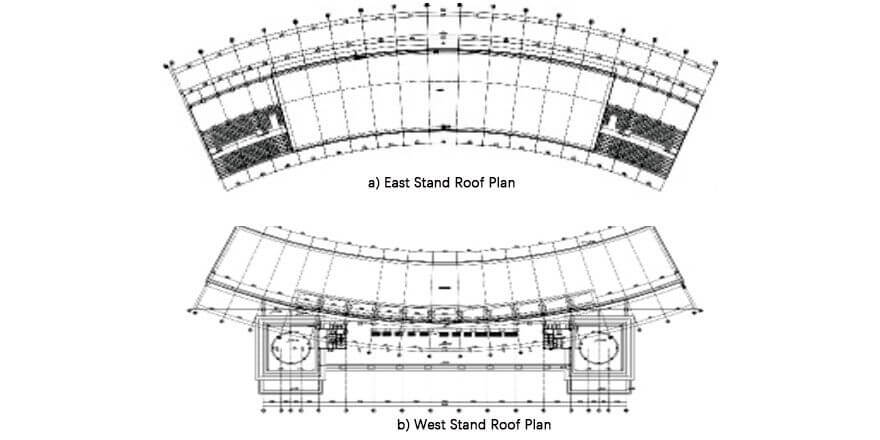

The total length of the football stadium is about 249.5m and the total width is about 246.3m. It is divided into four parts by setting seams, with a total area of about 21439m. The east and west sides are the bleacher’s canopy area (the west stand is the main stand), the lower part is a concrete frame structure, and the top of the upper stand is provided with a cantilevered steel structure stadium canopy. The total arc length of the west stand is 147m, the radial width is 22.9m, the total arc length of the east stand is 95.8m, and the radial width is 22.9m (single-span column spacing 8.1m + cantilever length 13.8m), cornice height About 23.700m, the column distance along the arc direction is 8.633m. (Single-span column spacing 8.1m + cantilever length 13.8m), the height of the cornice is about 17.910m, and the column spacing along the arc direction is 8.633m. The general rendering of the main stadium is shown in Figure 1, the roof plan of the East Stand (Figure 2), and the roof plan of the West Stand (Figure 3). This stadium canopy project is a Class C building, the safety level of the building structure is Class II, the seismic fortification intensity is 7 degrees, the design basic seismic acceleration is 0.15g, the design earthquake is grouped into the second group, and the site soil category is Class II.

Fig.1 renderings of the main stadium

Fig.2 a (East Stand Roof Plan) And b (West Stand Roof Plan)

2. The layout of the steel structure of the bleacher canopy

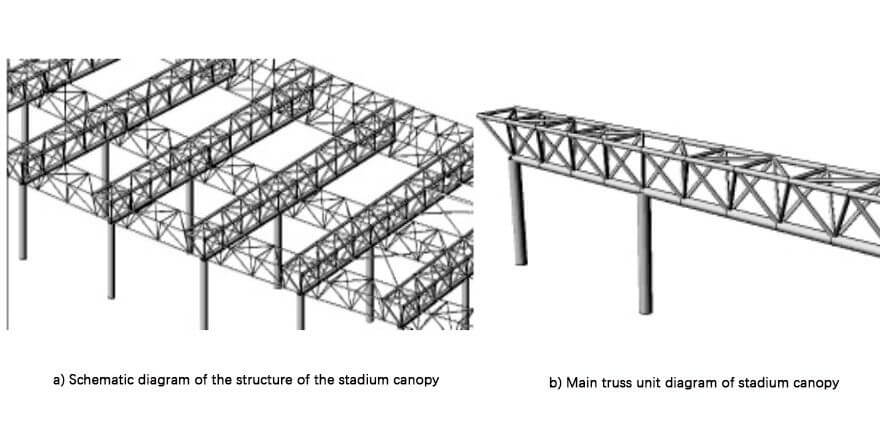

According to the architectural requirements of the stadium and the layout of the lower part of the building, through the comparative analysis of the application of different structural systems, it is finally determined that the cantilever stadium roof design structure with a double fulcrum is adopted, and the cantilevered stadium canopy adopts the form of steel pipe three-dimensional truss.

(1) Main and secondary trusses roof: Combined with the lower stand structure, the cantilevered stadium roof design main truss uses the columns under the stand as the front and rear fulcrums to form a force arm to effectively solve the overturning problem of the cantilevered main truss. The east (west) side grandstand canopy is arranged with 12 (18) main truss units in the radial direction along the column spacing of the lower structure frame, and the main truss spacing is 8.633m between the lower column space truss. The section form of the main truss adopts the inverted triangular standing canopy truss roof structure. (Figure 3)

Fig.3 a(Schematic diagram of the structure of the stadium canopy) and b (Main truss unit diagram of stadium canopy)

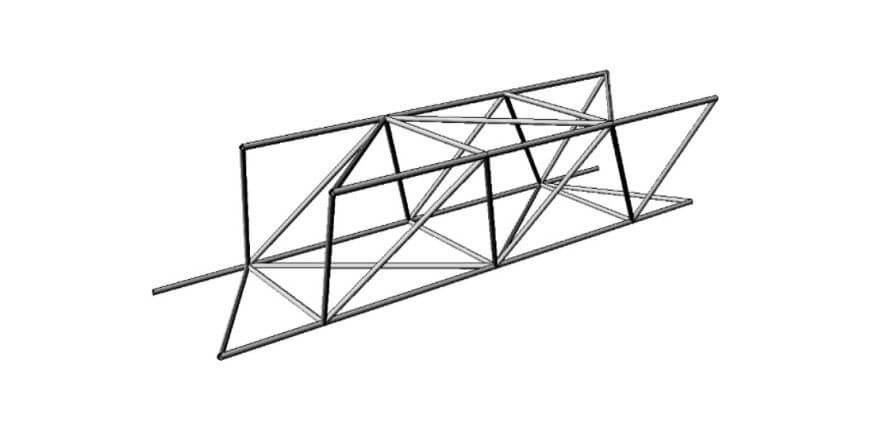

Three secondary trusses are arranged between the ring main truss units of the stadium canopy, two of which are inverted triangular steel tube secondary trusses, which are connected to the main truss chord at the top of the stand column, which not only ensures the circumferential load of the main truss It also provides a reliable anti-rolling system for the main truss, reduces the out-of-plane calculation length of the main truss, and effectively exerts the spatial effect of the entire structure. At the cantilevered tail of the main truss unit, the cross-sectional form of the secondary truss is combined with the requirements of the building to set up a circumferential maintenance catwalk, and a diamond-shaped secondary truss (Figure 4) is arranged as the channel for the maintenance catwalk. It plays a supporting role and enhances the integrity and stability of the entire shed roof structure.

Fig. 4 Sub-truss unit diagram of bleacher canopy

(2) The stadium roof support system is arranged to strengthen the overall stiffness of the roof system, and four roof horizontal supports are arranged at the upper chord spacing of the primary and secondary trusses. The stadium roof system consists of main trusses, secondary trusses, and horizontal supports to form a stable geometric invariant system.

Prev: Prefabricated Wide-Body Passenger Aircraft Parts Production Steel Structure Warehouse Construction