+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

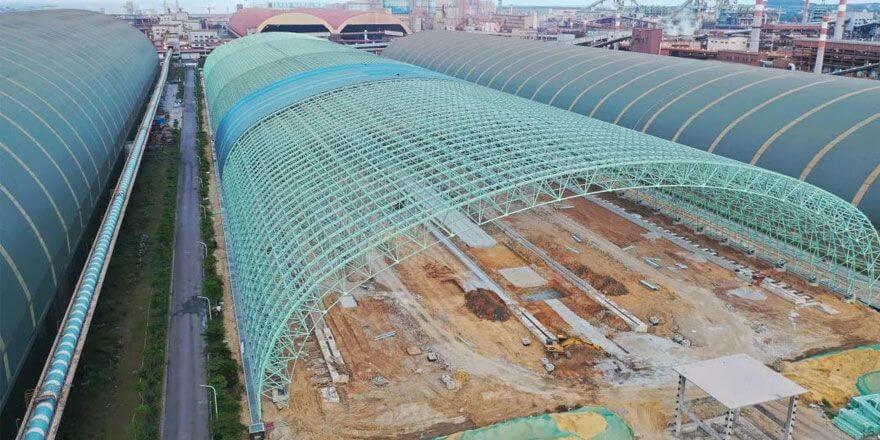

The raw material storage project in Zhanjiang mainly builds a new warehouse for the mixing material yard. The roof of the material yard building adopts a square pyramidal spherical space frame with bolt ball nodes upright, with a span of 110m and the highest elevation point of 31.8m; Supporting the construction of a crushing and screening system, receiving system, feeding system, civil engineering of water slag conveying system, electrical and automation, gas, general plan transportation, water supply and drainage, ventilation, and air conditioning.

Raw material engineering mixing stockyard warehouse project adopts an arched steel space frame structure system, arch height 31.8m, span 110m, length 500m, column spacing 8.92m, composed of four blocks A/B/C/D, with deformation joint 3 in the middle Road, the space frame adopts the high-altitude cantilever cumulative assembly (bulk) process.

The steel structure barrel vault shed project started to be assembled on the ground on November 23, 2019. On November 28, the starting span of the space frame of section B was successfully closed. After closing, the east and west sides were extended outwards for construction. The crane is hoisted to the designated location for assembly to achieve the purpose of the high-altitude cumulative assembly. After the construction of section B is completed, Sections C, section A, and section D shall be constructed according to the assembly method of section B. The advantage of the high-altitude cantilever cumulative assembly (bulk) process is that the entire assembly is always carried out on the ground at the start, avoiding high-altitude operations, reducing labor intensity, shortening the construction period, and ensuring assembly quality.

In the early stage of the installation of the roof space frame of the stockyard and factory building, the project management team planned in advance and discussed the deepening of the drawings, finally determined a feasible, easy-to-implement, and low-risk construction method, and compiled an expert demonstration plan. After completing the expert demonstration and entering the on-site construction stage, the safety control was strengthened, and finally, the construction of the last span was successfully completed on May 19, 2020.

Prev: International Airport Maintenance Hangar Construction Project

Next: Airport Terminal Steel Space Frame Structure Roof Metallic Building Construction