+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

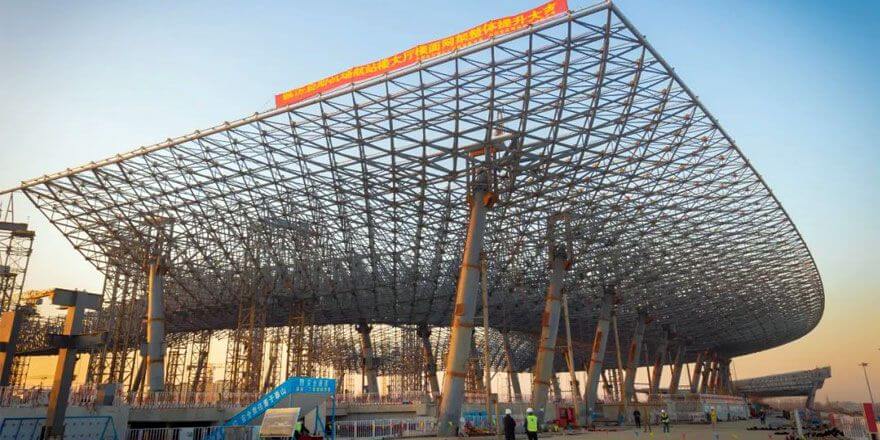

This steel structure project is an airport reconstruction and expansion project. The new passenger terminal building is located on the north side of the existing terminal building. The old and new passenger terminal buildings are effectively connected through the waiting corridor, and the appearance is integrated. After being put into use, it can meet the passenger throughput. 12 million passengers are needed.

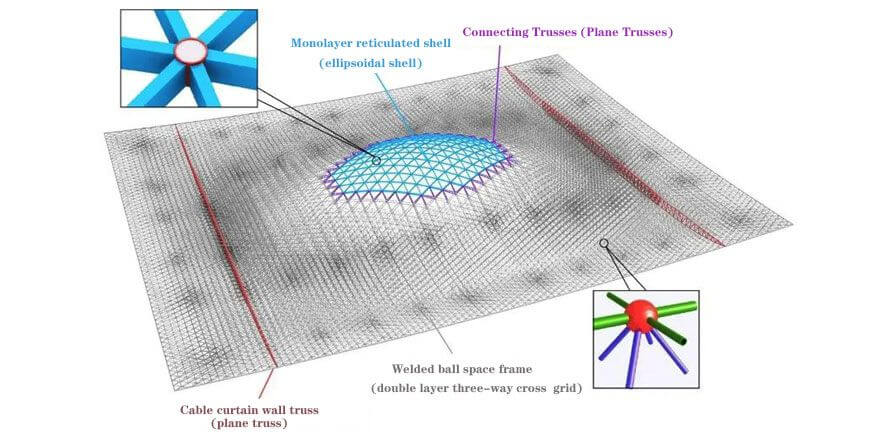

The roof steel space frame structure of the airport passenger terminal hall is a rectangular space frame structure supported by 56 roof support columns (inclined steel columns), with a projected size of about 237m×194m. The central area adopts a single-layer ellipsoidal shell (cylindrical node) with a plane of about 85m×108m, and the surrounding area adopts a double-layer space frame system (welded ball node), which is a three-way cross-space frame, in which the T-20 axis, T- A curtain wall truss with cables extending from east to west is installed on the top of the 29-axis columns.

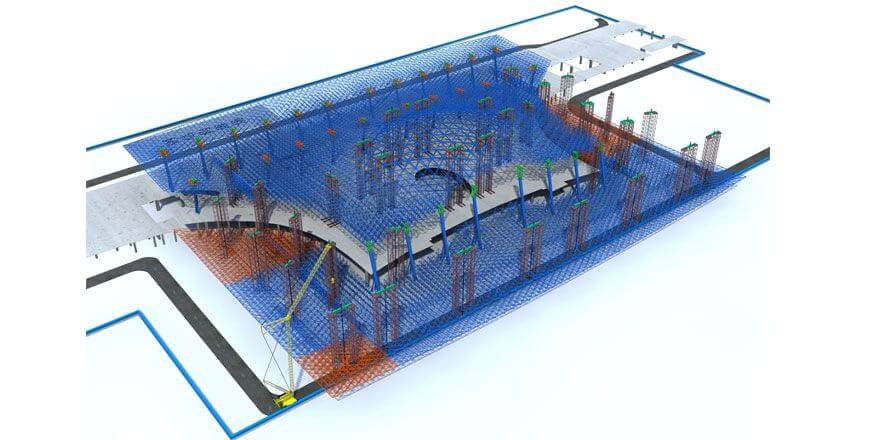

The space frame construction is divided into two areas. In order to upgrade the first area and the second area, the method of “in-situ assembly and overall upgrading” is adopted.

The first lifting area is the floor part. The total weight of the steel space frame is 3656 tons, the area is about 25400 square meters, which is equivalent to the size of 60 basketball courts, and the maximum span is 83 meters; the lifting height is 12.56 meters, and there are 40 sets of lifting A lifting pumping station took a total of 7.5 hours.

Since the assembly of the steel structure space frame, the project department has been using software to simulate the hoisting conditions, analyze potential unfavorable factors, and finally determine the optimal solution after multi-party demonstrations. The project strictly controls the welding quality during the space frame assembly process, implements the “real name system” for welds, manages in different areas, and assigns responsibilities to people to ensure that management responsibilities are consolidated.

In order to ensure the stability and safety of the space frame lifting process, the passenger terminal project adopts a synchronous lifting control strategy of “equalizing the oil pressure at the lifting point, adjusting the structure attitude, and synchronously controlling the displacement”. Before lifting, arrange for special personnel to observe the lifting points throughout the process, and feedback the monitoring situation to the on-site command room in real time. The command room conducts digital control of each lifting point through relevant feedback data; The mechanical characteristics (stress, strain and deflection) of the key beam units and truss units in the frame structure ensure reliable data support for the monitoring and analysis of the deformation of the steel space frame structure during construction, and ensure the safety and controllability of the overall improvement.